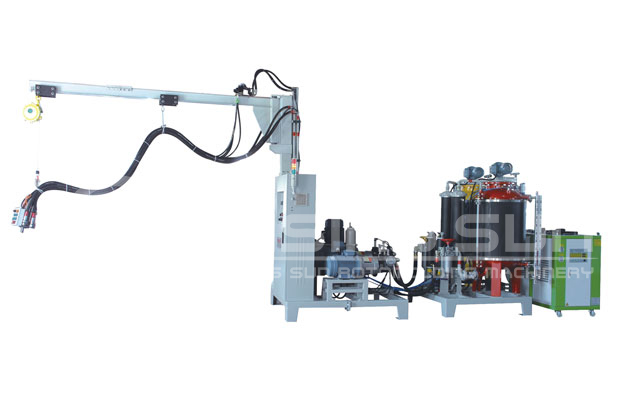

PU foaming machine is a professional equipment used to produce polyurethane (PU) foam. Polyurethane foam is a multifunctional polymer material with excellent heat insulation, sound insulation, cushioning and other properties. It is widely used in many fields such as construction, furniture, and automobiles. The function of PU foaming machine is to mix and stir the raw materials of polyurethane and promote its foaming reaction to produce foam products. In rotational molding, it is often used in the production of products such as cooler box and water floats.

PU foaming machine is a professional equipment used to produce polyurethane (PU) foam. Polyurethane foam is a multifunctional polymer material with excellent heat insulation, sound insulation, cushioning and other properties. It is widely used in many fields such as construction, furniture, and automobiles. The function of PU foaming machine is to mix and stir the raw materials of polyurethane and promote its foaming reaction to produce foam products. In rotational molding, it is often used in the production of products such as cooler box and water floats.

The main technical features of the equipment are:

★ Its foaming machine is compatible with foaming systems such as F11, 141B, 245fa and cyclopentane;

★ The mixing head for material injection can be freely moved from the front, back, left, right, and up and down directions.

★ After the black and white pressure needle valve is balanced and locked, it can ensure that there is no pressure difference between black and white material pressure;

★ Magnetic coupling adopts the high-tech permanent magnet control, without temperature rise, or leakage;

★ It can automatically clean the gun after the mixing head is injected with materials;

★ The injection program is 24 stations to meet the production of multiple products;

★ The mixing head adopts dual proximity switch control to achieve accurate injection;

★ its function for soft start of fequency converter and automatic switching between high and low frequency, low carbon energy saving and environmental protection can reduce energy consumption greatly;

★ All digital and modular integration control all process flow, it is accurate, safe, intuitive, intelligent and humanized;

★ The single-component measuring feeding material of mixing head is more accurate than the material feeding ratio of the return pipe;