Ice cooler is one of the important application of rotational moulding. It is very popular with customers because of its durability, friction resistance and heat preservation effect.

The main application areas are as follows:

1)Outdoor sport

2)Fresh storage

3)Camping

4)Fishing

5)Others.....

According to the research report "2021-2025 China Insulation industry supply and demand Forecast and development prospects research report" in 2020, the global Ice cooler market scale reached 1.905 billion US dollars (equivalent to 12.73 billion YUAN), China's Ice cooler market scale is 230 million US dollars (equivalent to 1.541 billion yuan) . And Global market size is expected to grow at a compound annual growth rate (CAGR) of 4.99% in the future.

If you are also considering entering this industry, we would be happy to provide a full support package.

1)Model selection:

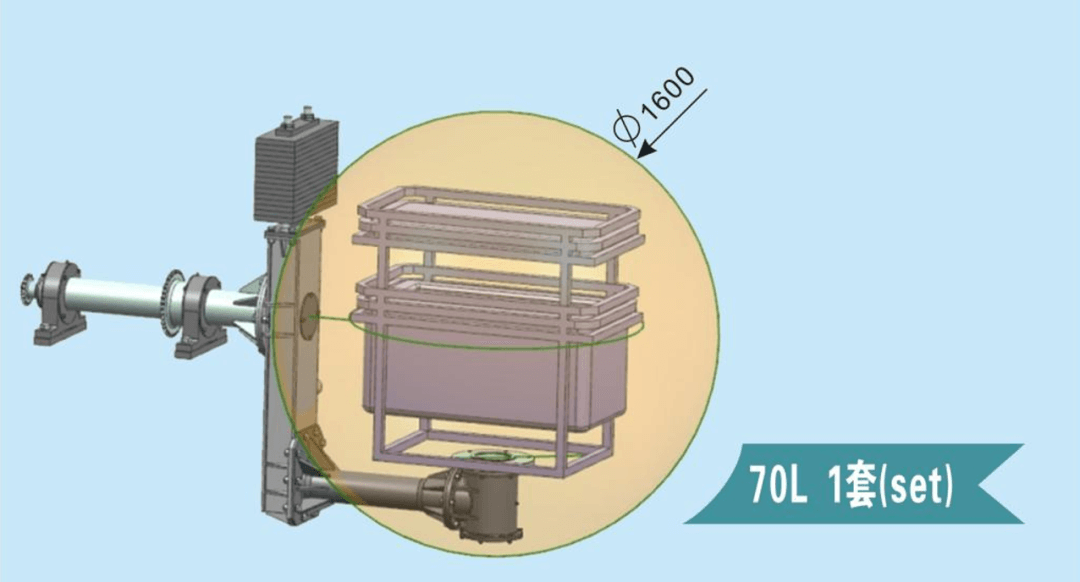

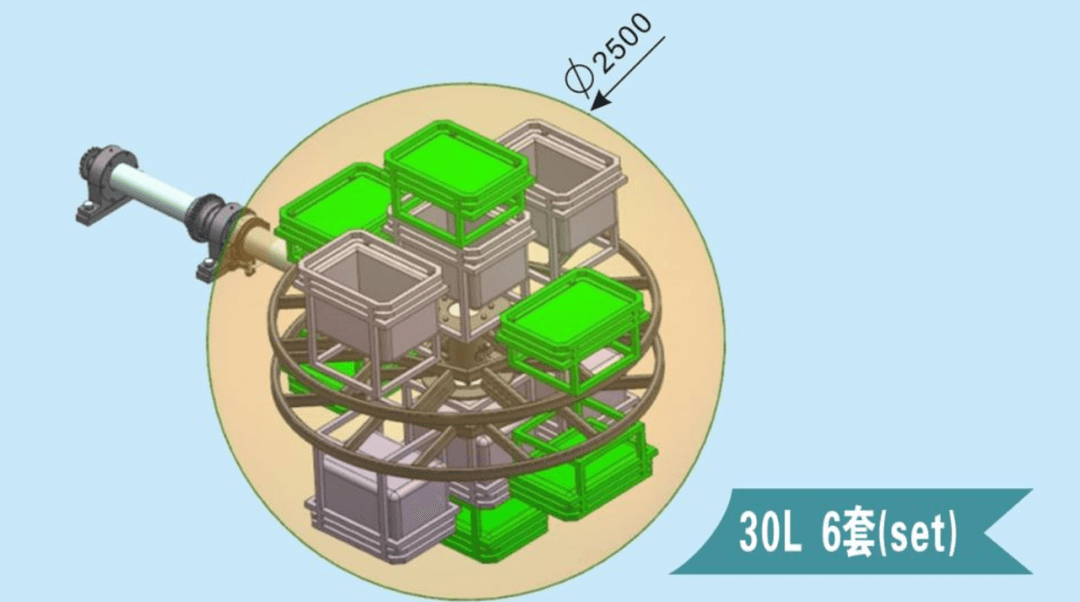

We will recommend suitable models according to your production requirements.

2)Mold design and placement:

According to the existing product drawings or design drawings, confirm the mold loading on the machine. Fully consider the following points, such as reducing the difficulty of demoulding, improving production efficiency and ensuring product quality to better design and place the mold.

3)Mold display:

We will recommend the mold suitable for your needs. For some Ice cooler which have complex design and deep cavity structure, we will recommend aluminum mold. The surface of the products made by this mold is beautiful and the product precision is high ; For some large and medium-sized ice cooler with relatively simple structure, we will recommend the steel mold. The mold has long life and fast heating.

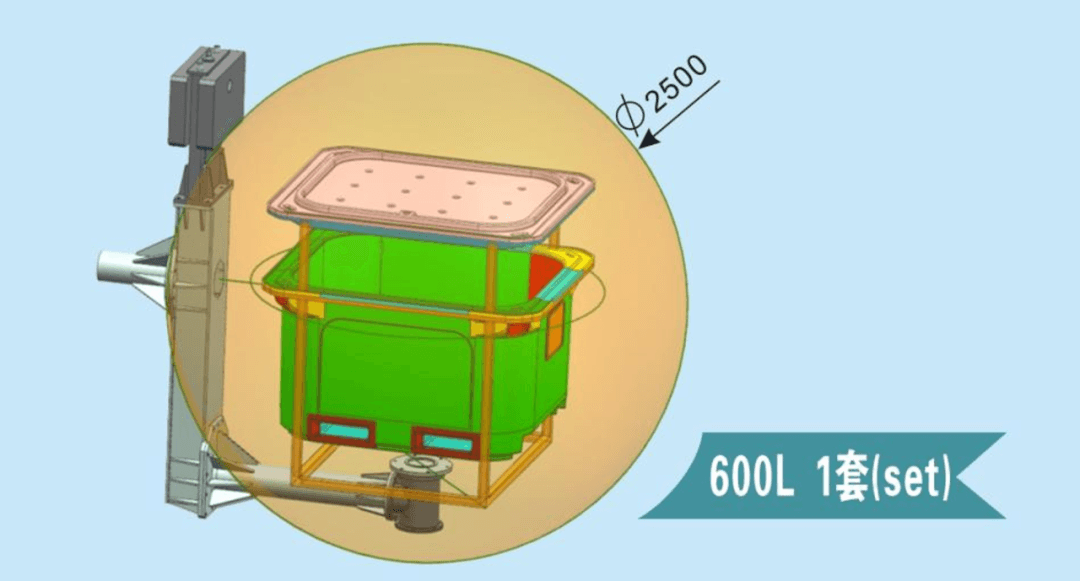

3)Foaming tools recommended:

The production of ice cooler mold will generally be matched the corresponding structure of the fixture mold at the same time, with the purpose of making the product to achieve high quality foaming effect and heat insulation effect! The ice cooler that has just been removed from the rotational moulding mold and has a certain temperature is placed inside the fixture, which can prevent deformation caused by excessive pressure of the insulation layer in the foaming process.

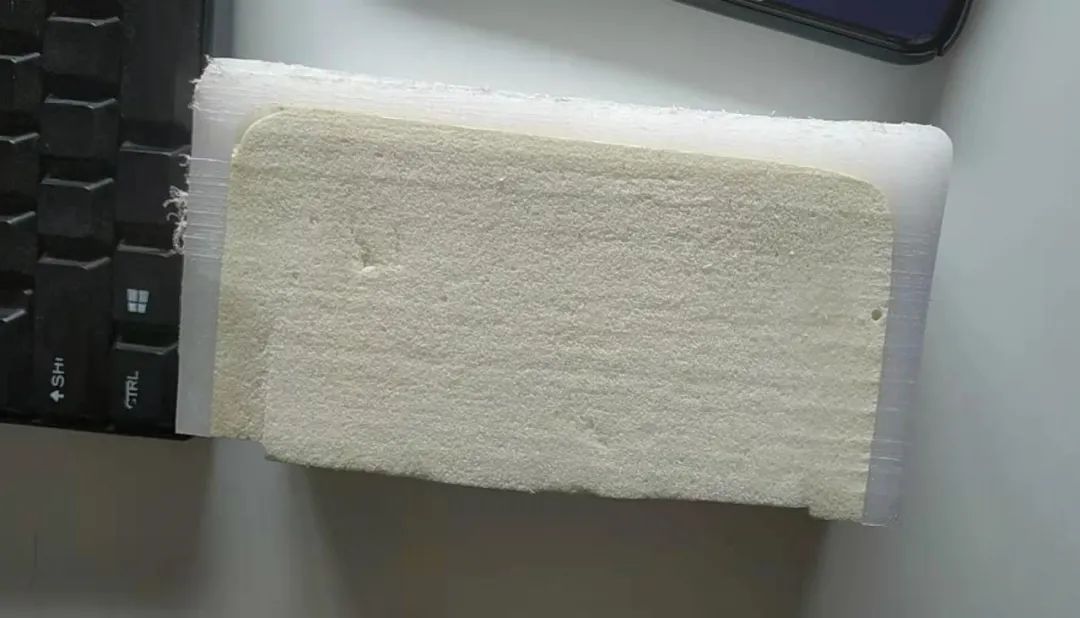

PU (polyurethane) is the most commonly used insulation material at present. Because of its low thermal conductivity and high cost performance, it has become the main insulation material of the ice cooler.

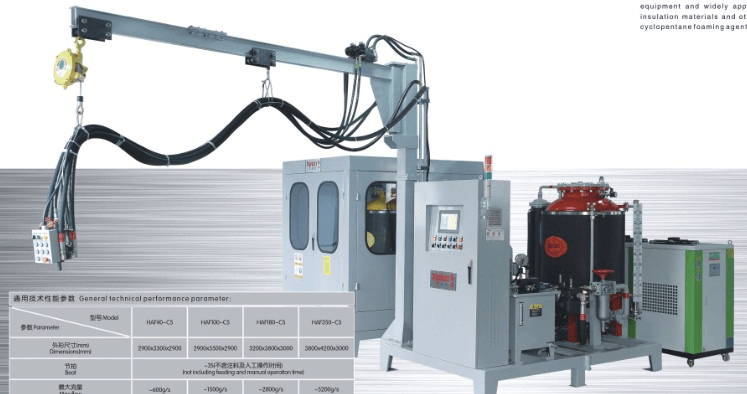

If you need, we will also recommend some foaming equipment for you.

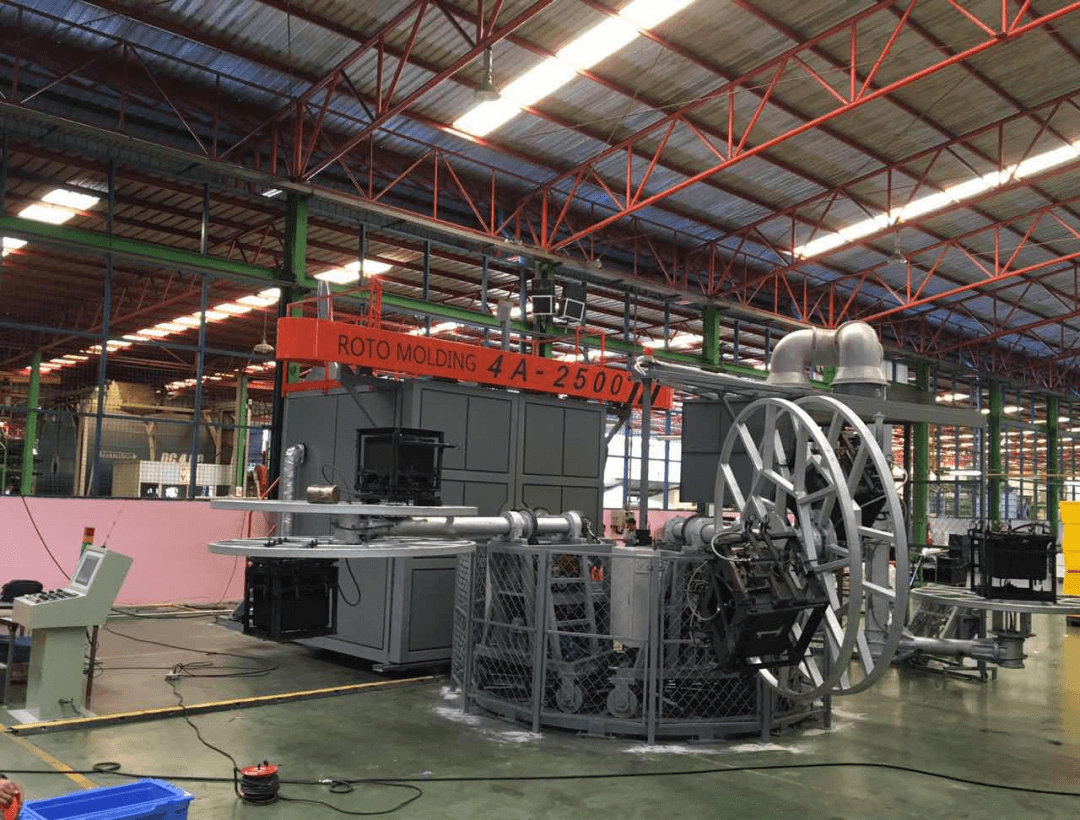

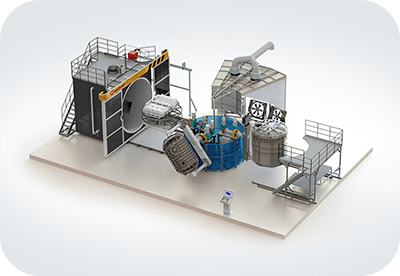

Take a look at our customer's production line