Case Sharing-transportation facilities

Many transportation facilities are also made by rotational moulding, such as

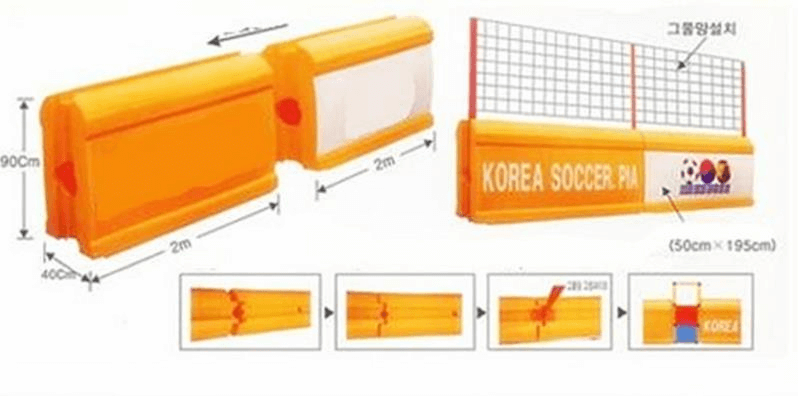

1) water-filled barrier

2)anti-collision bucket

3)Riot disorderly water-filled barrier

4)warning signs

5)crash bearer

6)fence

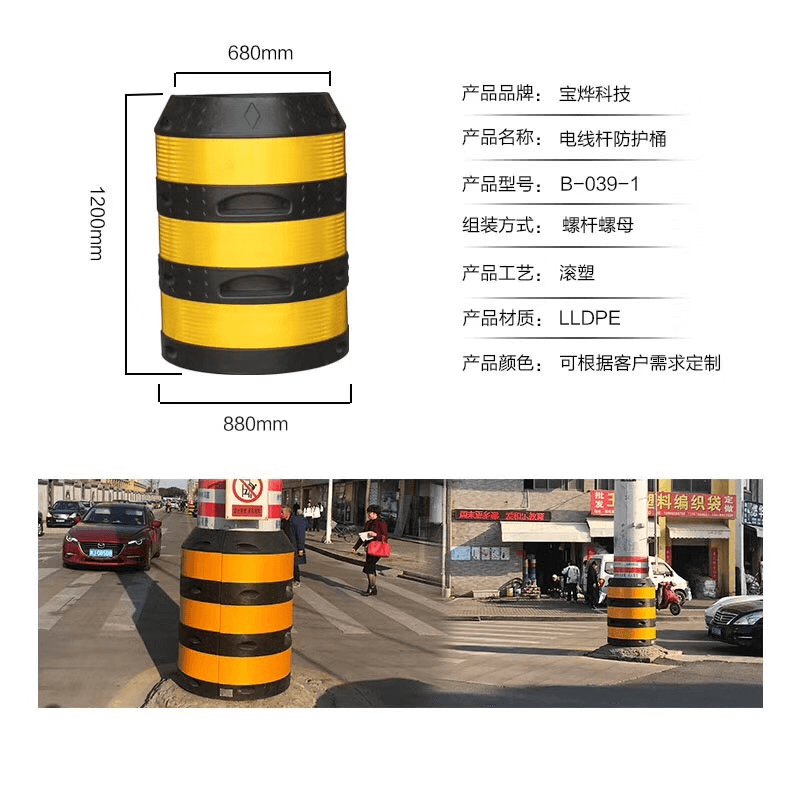

7) protective barrel( utility pole)

It can be said that most plastic transportation products can be produced by the rotational moulding process!

In recent years, the rotational moulding began to replace the traditional blow molding. That's because rotational molding has certain advantages over blow molding:

01 Low equipment / mold development cost;

02 strong design-can shape more complex product structure;

03 convenient color change & product replacement production ;

04 strong ability of anti-deformation, anti-impact and anti-puncture;

05 less waste and scraps in production;

06 controllable product wall thickness ;

07 .......

The disadvantage of rotational molding is also obvious, that is, the production is relatively low. In view of this, we have made more efforts and continuous improvement.

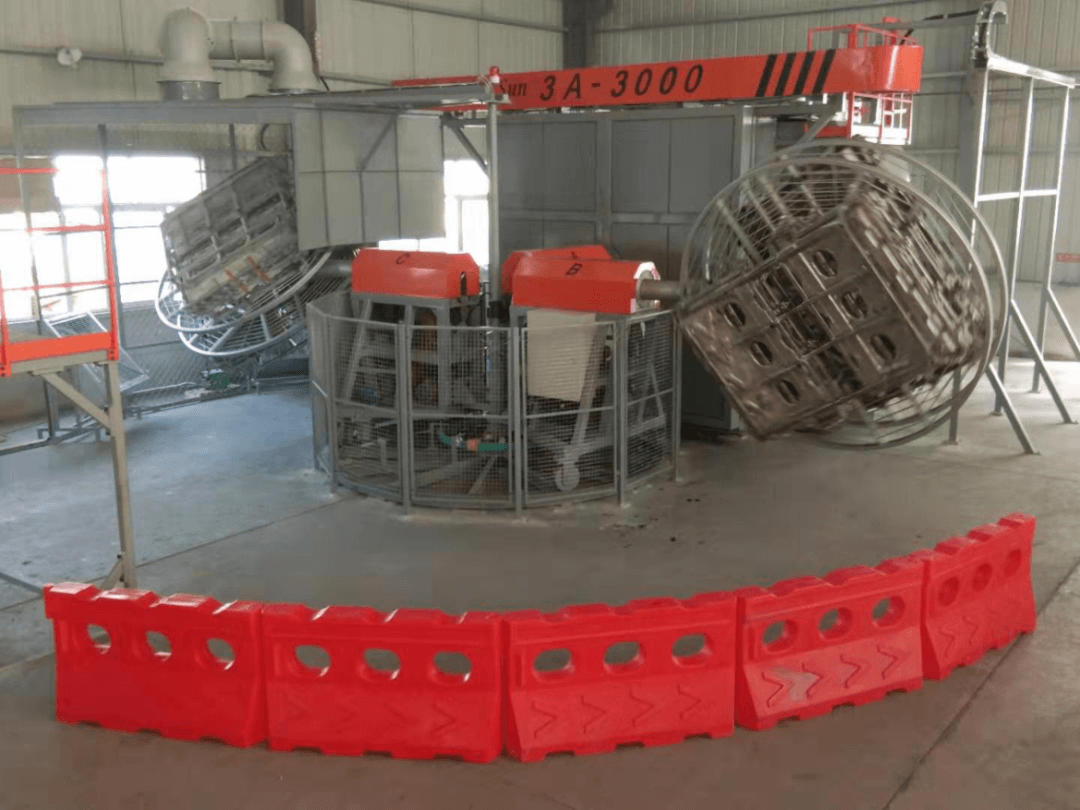

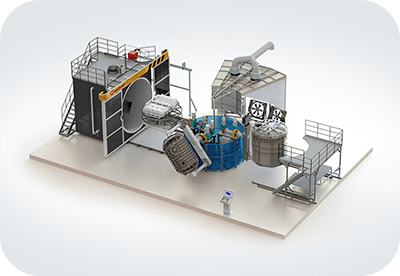

01 Selection of equipment

The high efficiency production can be realized by selecting suitable rotational molding equipment, such as carrousel rotational molding machine.

Each machine is equipped with 3-4 rotating arms. When one arm is heated, the second arm is cooling and the third arm is disassembled.

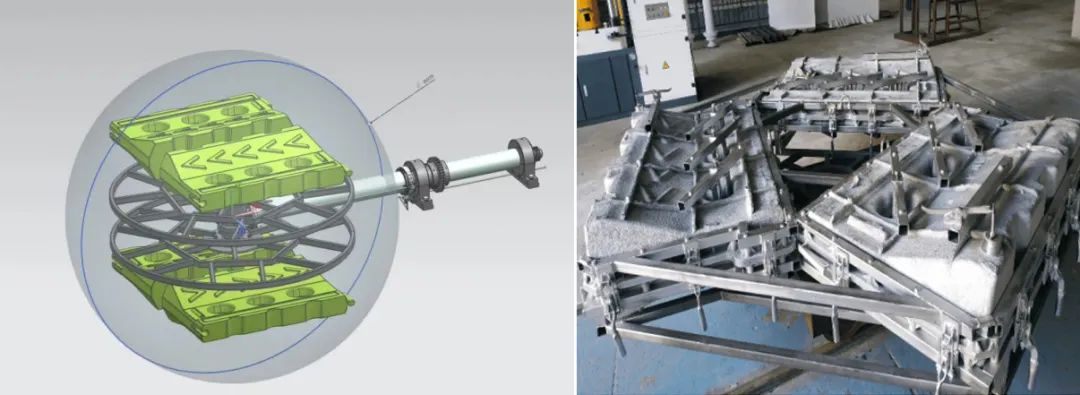

02 Mold design:

Work efficiency can be improved by using quick clamps.

A rotating arm can be equipped with 4-6 sets of mold,every heat cycles can product 4-6 set of products; The one-piece mould framework can help the mould to be disassembled in one time.

Through our efforts and continuous improvement, many large domestic manufacturers have begun to use our equipment for mass production! Our company will continue to better our solutions, which will bring new experience to our customers!