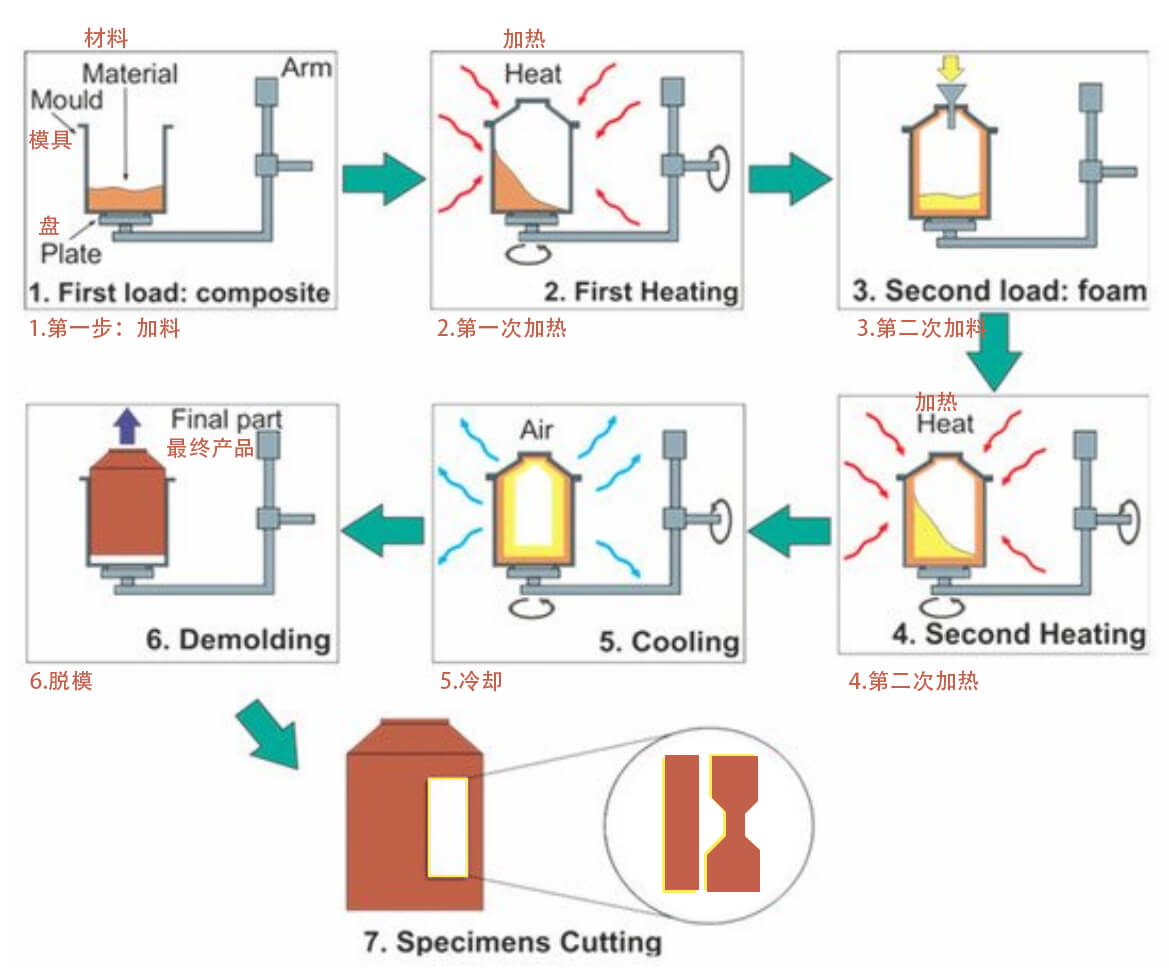

Many rotomolding products need to be fed twice or even several times in the production process! How to safely and effectively carry out secondary feeding is a subject we have been studying!

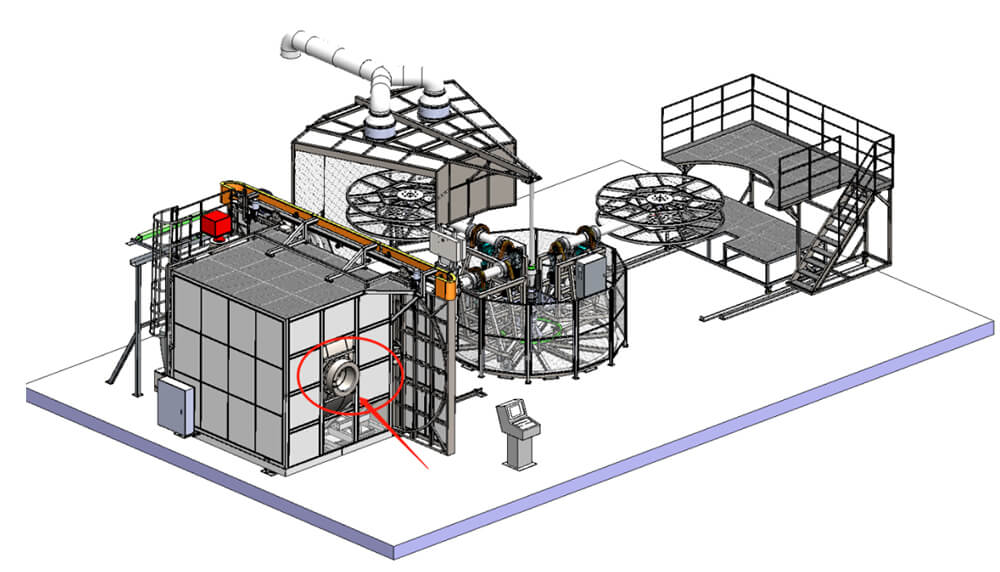

General process flow chart for multiple feeding

The feeding mode of open fire equipment is simple and direct, and the moulding mouth is directly fed through the feeding funnel!

1)Traditional manual feeding

Oven doors need to be opened for manual feeding, which increases heating time and energy consumption. It may also have operational-safety issues so that it have been abandoned by many companies.

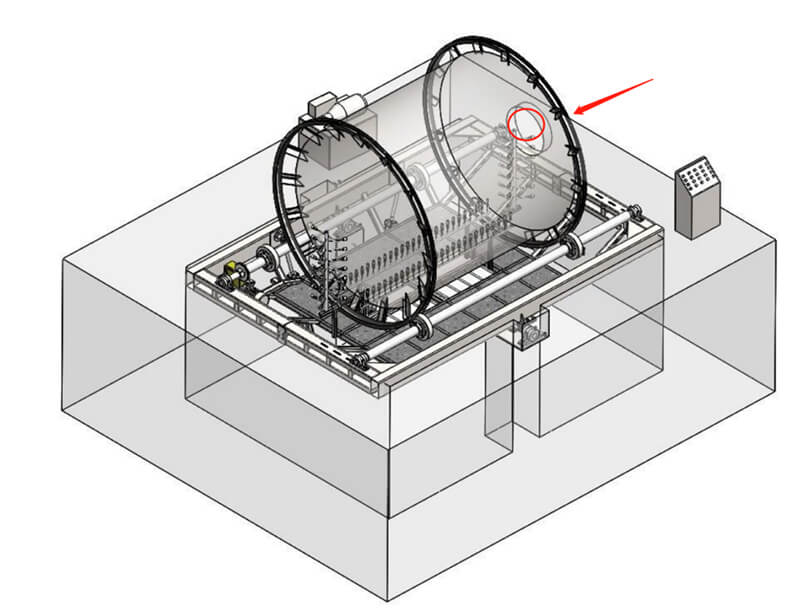

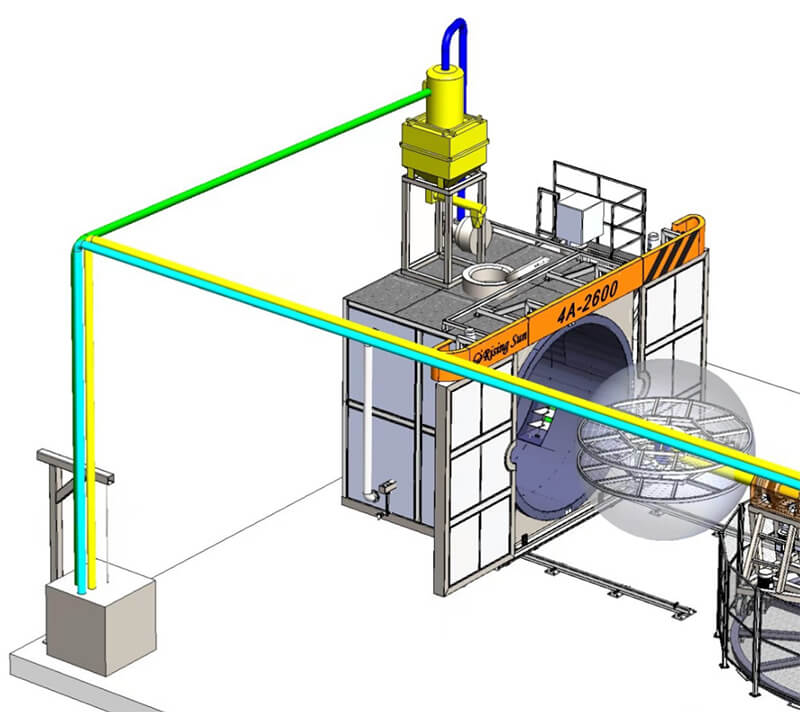

2)Feeding from the top of oven

The opening is reserved at the top of the oven, and the powder is injected into the mould through the feeding funnel in conjunction with the positioning of the revolving arm. This way guarantees the continuous high temperature in the oven, reduces energy consumption and makes operation safer. At present it is a widely used way.

It can also be used for secondary feeding through automatic weighing, transmission and batching systems!

3)Multi-layer feeding on side wall of oven

It can be operated with the feeding system to make it safer and faster.

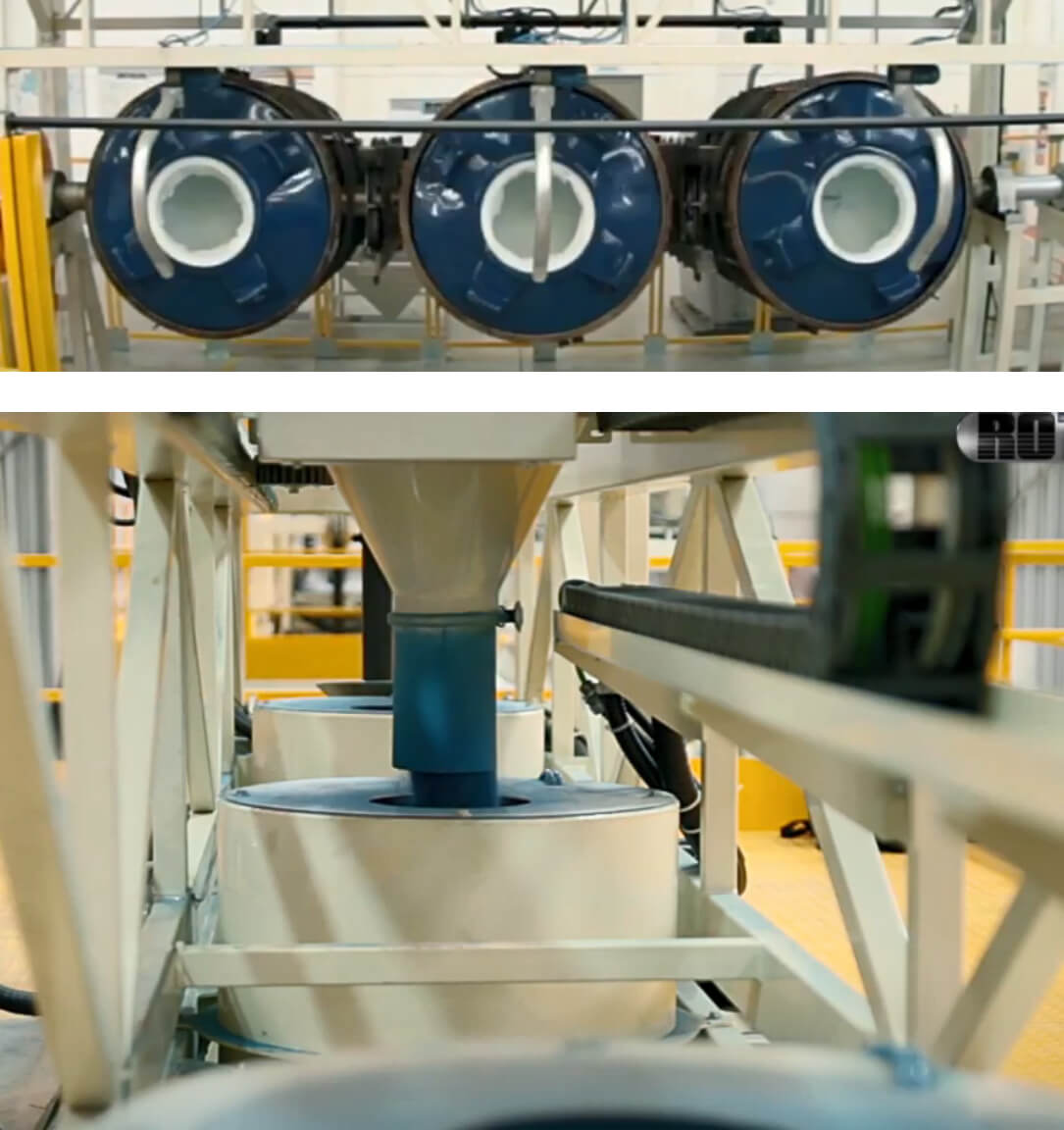

4)Secondary feeding funnel

A temperature-insulating funnel is designed; The automatic feeding of the feeding funnel can be realized with the pneumatic system. It can realize multi-layer, multi-color and multi-material processing, such as PE foaming.

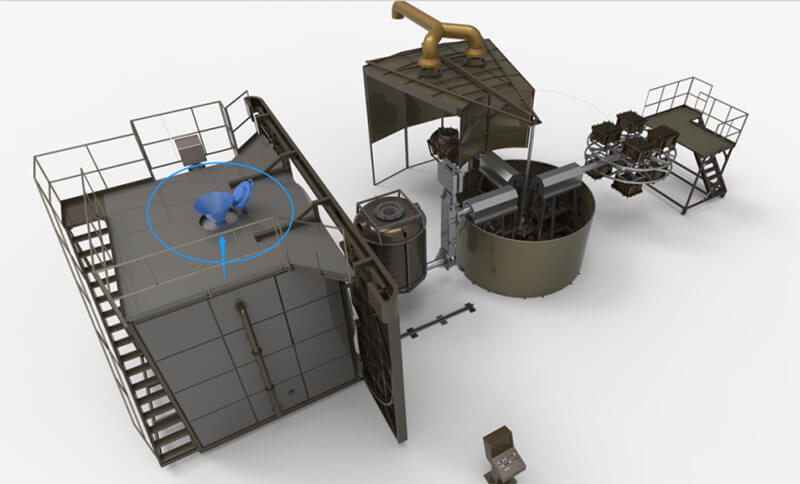

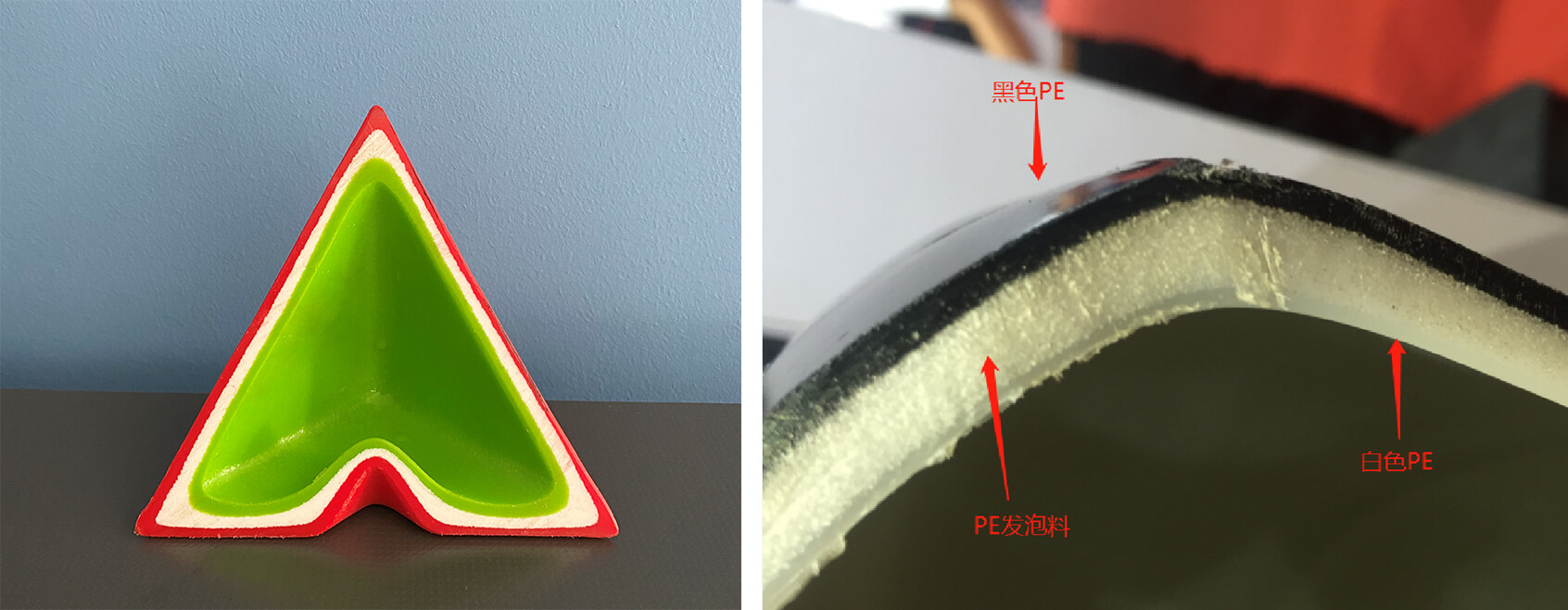

5)Other multiple feeding methods

Automatic feeding outside the oven

Multiple feeding products section diagram

If your rotomolding products need multi-layer feeding, please contact with us, maybe we can find more ways!