Advantages: 1.The price of the shuttle rotomolding machine is cheaper than a carousel machine of the same specification; 2. This machine is suitable for producing large and super-large rotomolding products; 3.This machine is suitable for simultaneous production of products with large time differences at each molding stage; 4.The oven has undergone CAE heat utilization simulation analysis, with high heat utilization rate, fast heating rate, energy saving and environmental protection;

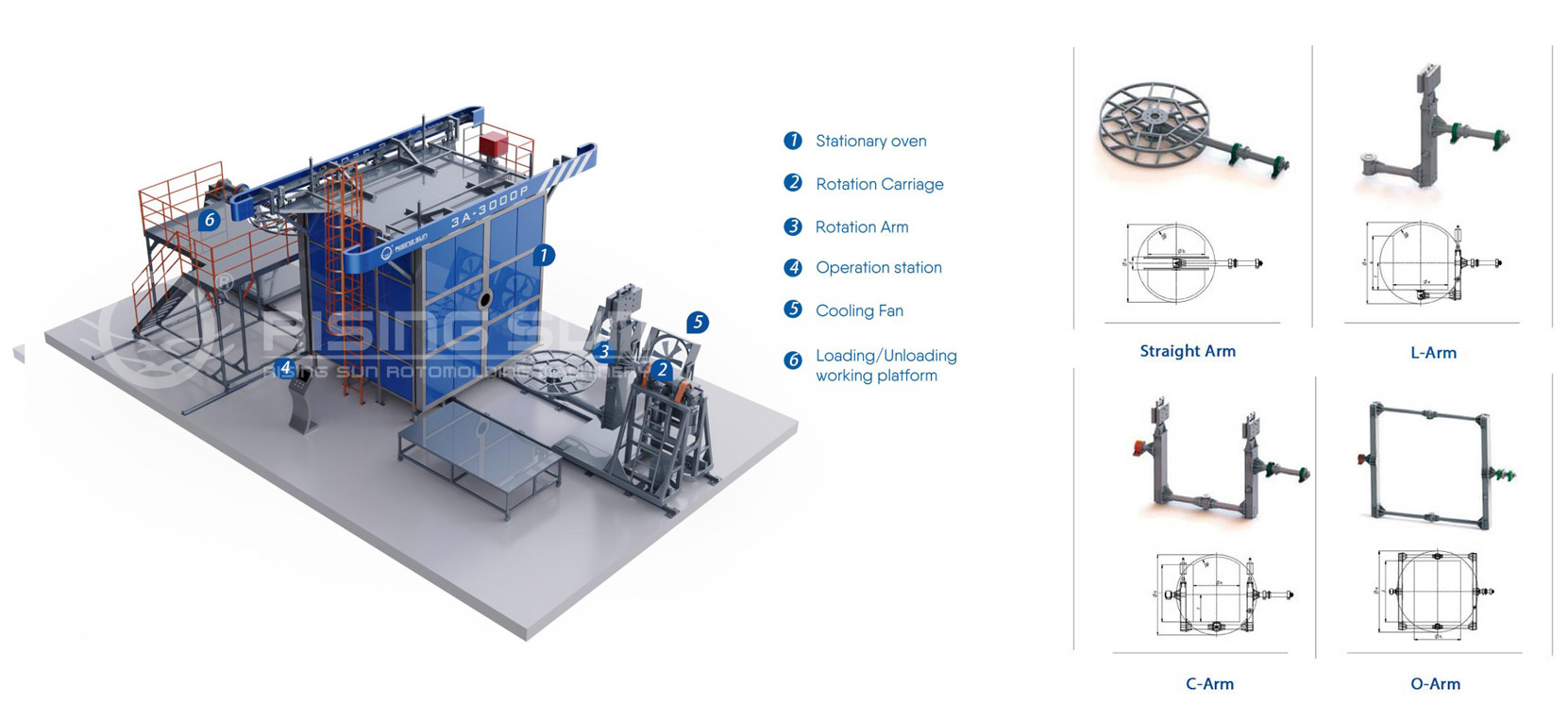

FEATURES OF SHUTTLE MACHINE

The shuttle machine is suitable for products with different production process requirements, large product differentiation or small batches; because the large shuttle arm is supported at both ends, it is also suitable to produce large and super large rotomolding products. It can also produce multiple small and medium-sized products. The advantage is that the footprint is small, and the investment is relatively low, when compared with other rotational molding equipment of the same specification.

MECHANICAL PART

· The equipment is modularly designed and manufactured;

· The cylinder oven has high space utilization and low heat absorption;

· Anti-deformation design of the oven door contributes to improve security;

· Real-time monitoring of oven temperature helps reduce energy consumption and improve efficiency.

Oven: it passed the CAE test and verification and the temperature in the oven is uniform.

HEATING CHAMBER:

1. The hot air is blown into the oven through the circulating fan below the heating chamber, the remaining hot air can flow into the heating chamber for recyle use. This design helps makes the powder less likely to accumulate and thus prevents fire.

2. The interior of the heating chamber is made of stainless steel, which is durable.

3. The thermal cycle fan and dual cooling system are conducive to durable and stable output.

Rotating arm and head are fully enclosed design, adopts casting and forging process. The performance is improved to be safe and reliable after heat treatment.

Bearing capacity of rotating arms: Mechanical CAE Analysis.

Ventilation function of rotating arm: Can adjust its thickness to be uniform;

COMBUSTION SYSTEM

We offer three brands of burners: Italian Riello, German Weishaupt, and American Maxon. Customers can choose according to their actual needs.

Natural gas, liquefied gas, diesel, etc. can all be used on the machine.

CONTROL SYSTEM

PLC control: Siemens’s PLC manages data over Ethernet with standardized circuit.

Each arm can be set up three stage heating, and each stage can be set up with different heating temperature, time, major and minor shaft speed, and circulation fan speed.

Cooling function: include air cooling and water mist cooling. It can can 3 stage coolings, each stage can be set up with different cooling time and delay.

Recipe function: create production parameters of corresponding products.

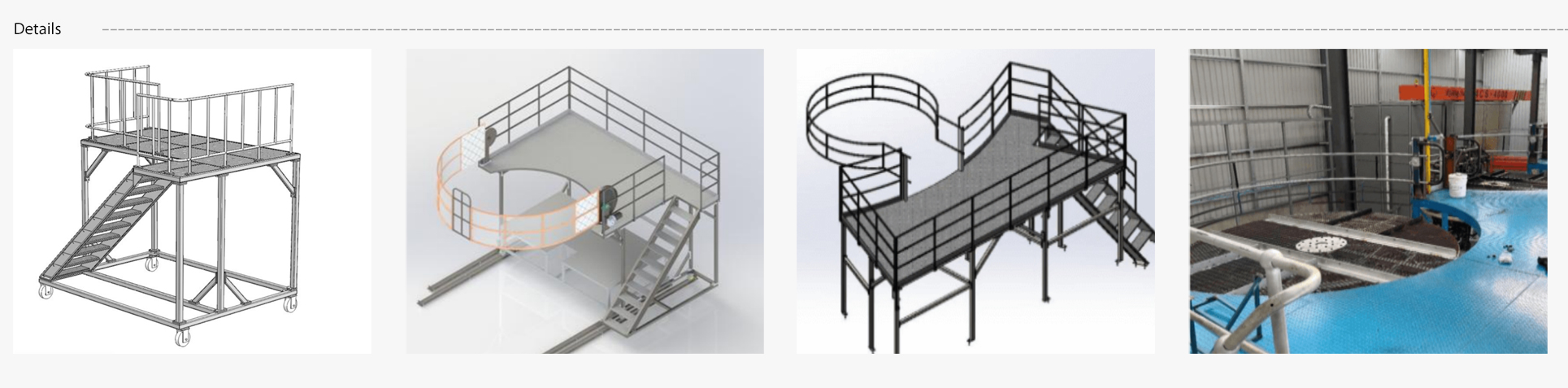

The station of loading/unloading is fixed, which can improve the efficiency.

Loading/unloading station: the rotating arm is wireless remote-controlled.

OTHER

When other rotating arms change molds, the machine can continue production.

Producible materials:PE, XLPE, PP, PA, PA6, PA12, PVC, ETFE.

OPTIONAL

1. RSTC--Wireless inner mould temperature measurement device

(1)Real-time transmission of in-mold temperature changes during heating process

(2)Monitor the temperature of different parts of the mold, such as the inside and outside parts , upper and lower parts;

(3)Real-time monitoring of temperature inside and outside the mold during heating forming;

(4) Real-time transmission of temperature during cooling.

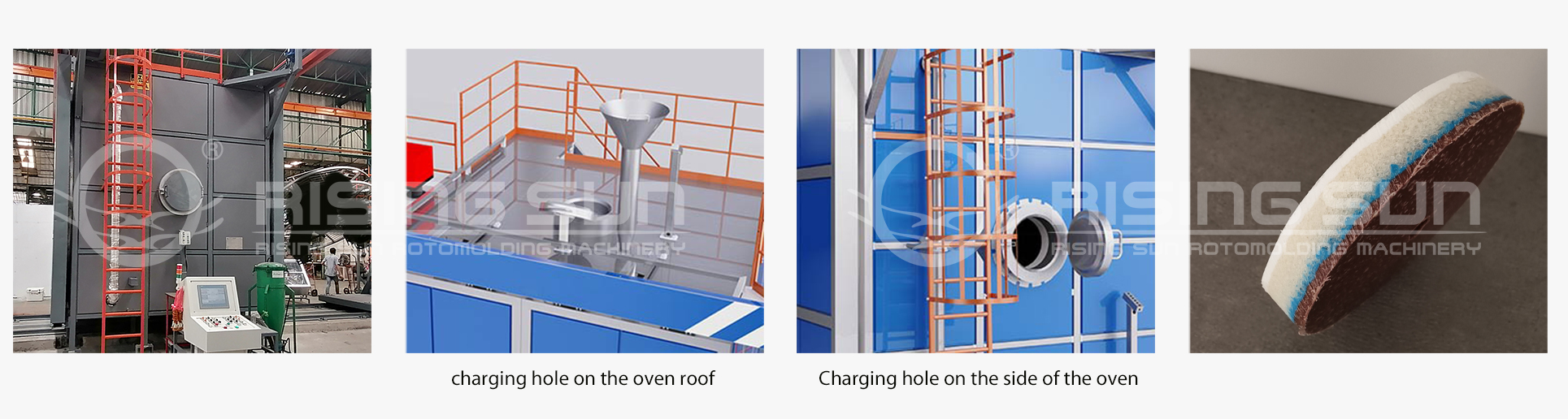

2. SECONDARY CHARGING SYSTEM

(1)Produce multilayer products

(2)Produce products in the color of camouflage

(3)PE foaming can be achieved;

3. ENCODER

Local thickening can be performed deep cavity products can be produced to adjust the thickness; products in the color

of camouflage can be produced

(4). Load Ranger--Automatic feeding weighing system

(5). Safety protection at demoulding station

ARM TYPE

CUSTOMER CASE

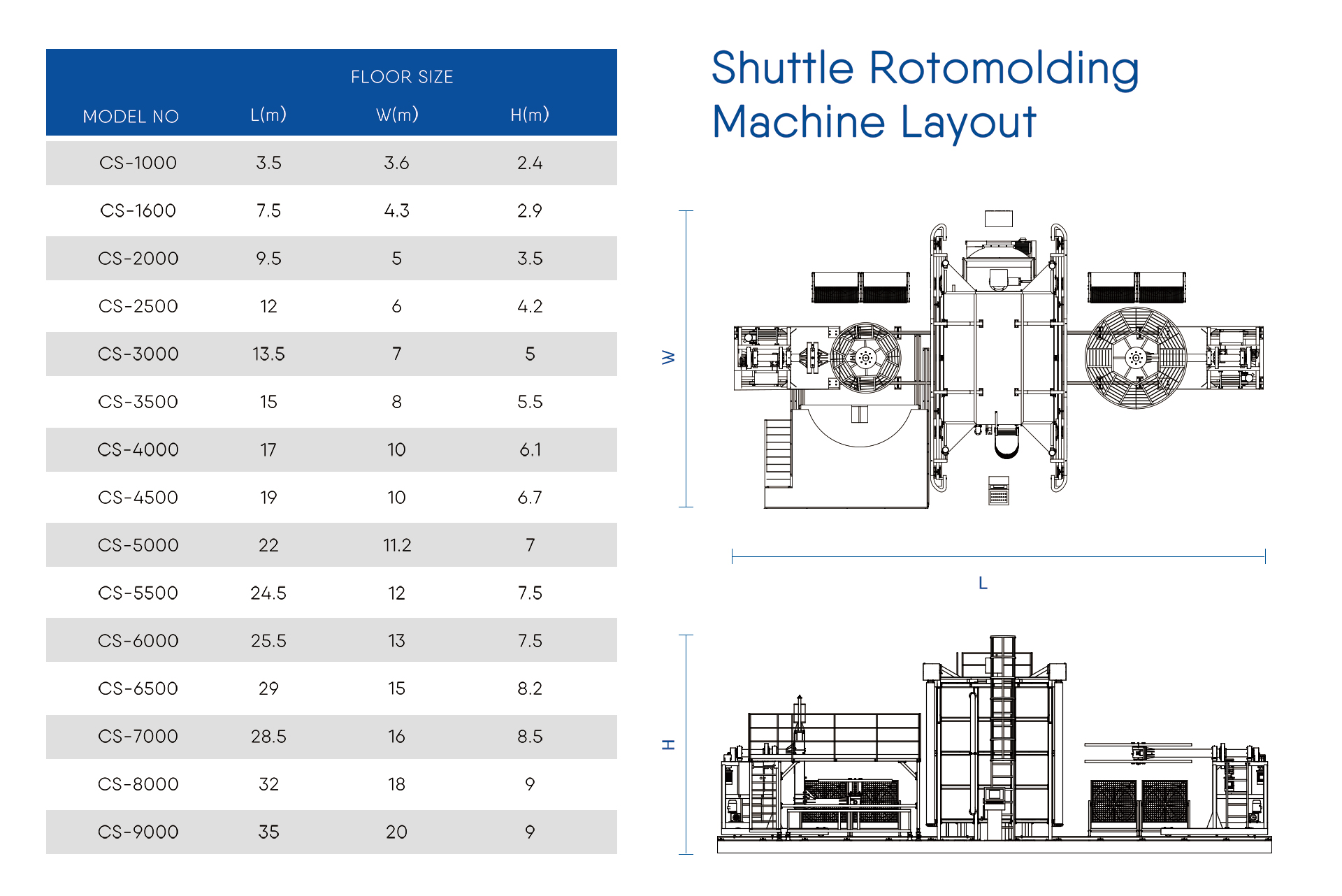

PRODUCT PARAMETER