Advantages: 1.Fully electric heating 2.Heating is more direct, the heat is directly used to heat the mold, which is more efficient 3.Different temperatures can be set in different areas to better control the wall thickness of the product

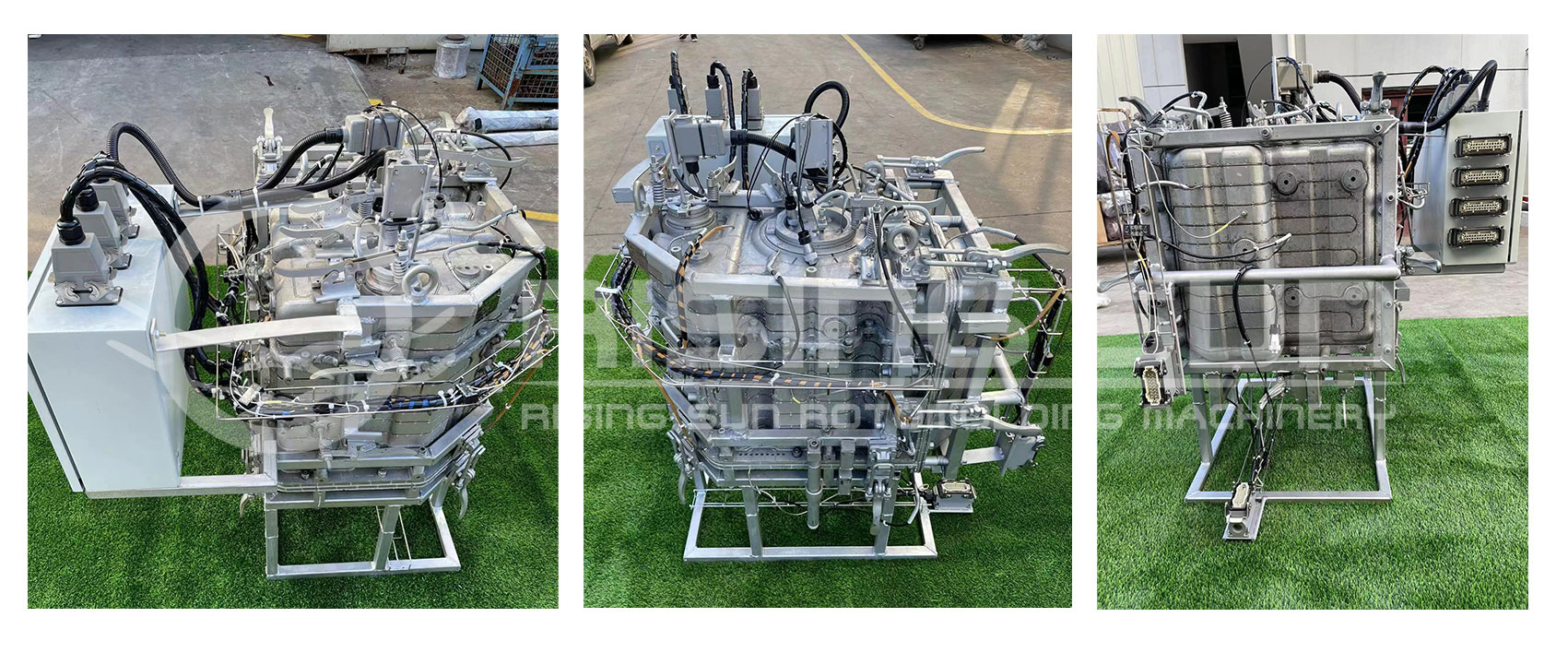

FEATURES OF MOLDS

The electric heating molds made by Rising Sun Rotomolding are generally made of CNC aluminum, the mold surface is covered with grooves for inlaying heaters. Electric heating molds are generally used for high-value, high-performance products, including hydrogen liners, scrubbers, fuel tanks, etc. A single mold can be set with multiple different heating temperatures and heating times to better control the molding effect of the product.

Our service is not limited to the production of molds, we will have mold drawings for you to confirm before production and mold proofing will be carried out after the completion of the mold to check its quality.

(1) Our Sales Manager will guide you through the whole process, including ideas, sketching, 3D models, tool design and final products. According to the actual model or product mapping, a three-dimensional model can be obtained.

(2) CAE analysis of temperature, load bearing, etc.

(3) Can accept different levels of inner/outer surface treatment.

(4) Molds can be put on the different arms, finding the position to make the production more stable and smooth;

(5) According to customers’ requirements, composite molds can be customized, such as carbon fiber mold.

(6) Product assembly and testing can be achieved.

(7) Multiple sets of molds can be disassembled at the same time with the help of integrated mold base.

(8) Ejector pin design creates air between the mold and the product, which is easy to separate and reduces the probability of product damage caused by demoulding.

(9) PTFE ventilating pipe is heat resistant, which can eliminate the internal stress of the mold.