Since 2008, Rising Sun has provided a full range of rotomolding solutions for customers in various fields around the world!

With the accumulation of solutions, we have achieved customer cases in 60+ countries, and this year we will break through 70+ countries! And the application fields of rotomolding are countless!

Today we are going to share a water treatment production line!

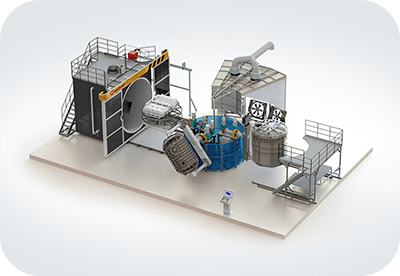

The customer customized a 3A-4500 machine, which has 3 rotating arms, each of which can hold a large water tank mould!

The customer originally did injection moulding and extrusion. After years of production, it was found that the injection moulding tank body had high stress, which was easy to cause warping and excessive displacement, resulting in the thread structure and size not meeting the requirements and being scrapped. The production cycle of FRP storage tanks is long, and there is no way to continue to produce quickly. The product is difficult to repair when it is damaged, the recycling cost is high, it is not environmentally friendly, and it is easy to cause secondary environmental pollution.

Finally, by comparing various processes, we understand that rotomolding is the perfect process to solve these problems!

Rotomolding is a stress-free one-piece moulding process. Low-cost mould customization can make various high-quality tank designs. The color can be changed at any time. Seamless one-piece moulding, strong structure, durable, and recyclable materials! A truly environmentally friendly process!

The mould was also developed by Rising Sun!

We combined the analysis of arm placement, force analysis, assembly and disassembly difficulty, production efficiency, etc. to customize the mould, which can not only produce high-quality weld-free water tank products, but also make the production process smoother and safer.

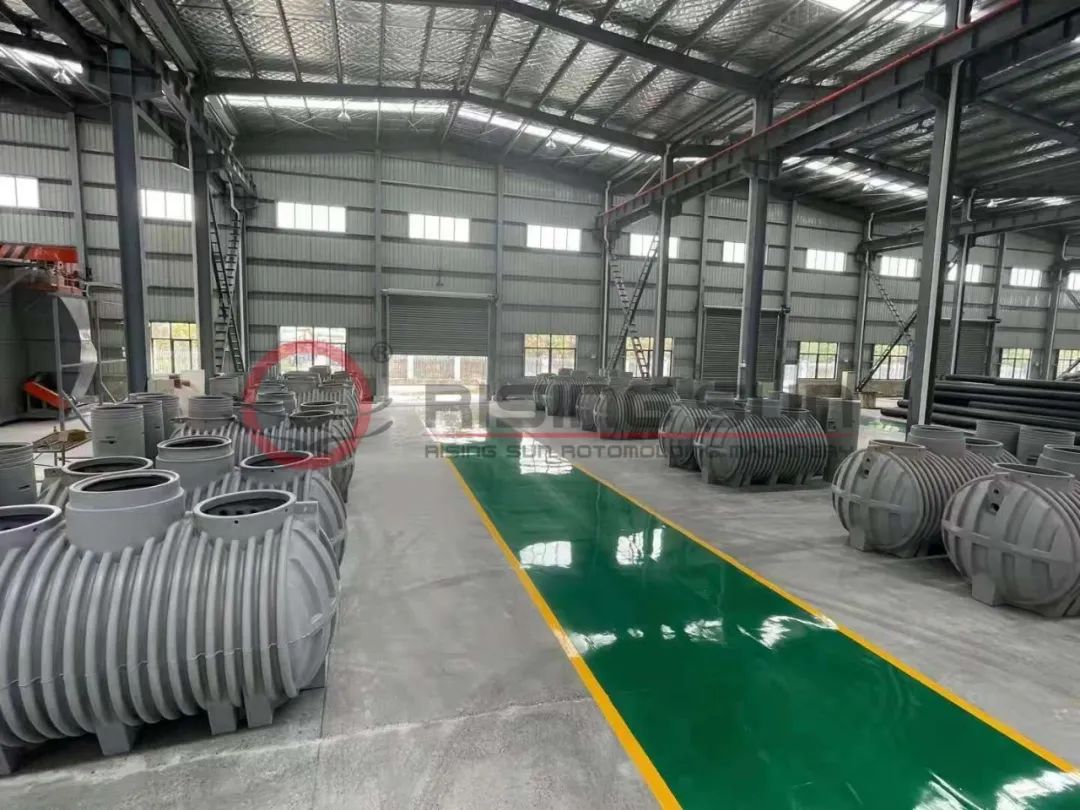

When we visited the customer's factory, we were shocked by the scene in front of us!

Just like the seeds that were planted at the beginning, they have become towering trees! This is enough to show the domestic demand for the application field of rotomolding water treatment, and everyone's desire for environmental improvement is getting stronger and stronger!

Analysis of the reasons why this type of tank can gain market recognition

(1) Strong design and low cost;

(2) Durable

(3) Customizable color;

(4) Adjustable wall thickness

(5) One-piece molding, seamless and leak-free;

(6) Can be made into multiple layers;

(7) Strong structure, strong toughness and corrosion resistance;

(8) Environmentally friendly and recyclable materials

..............

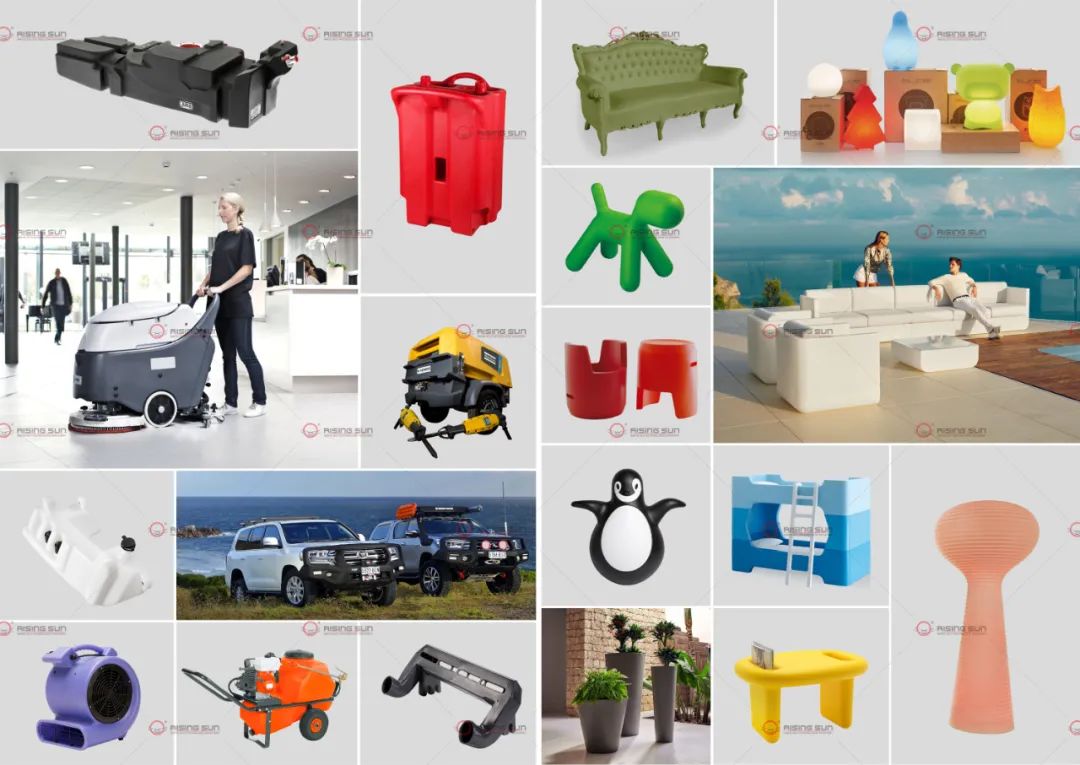

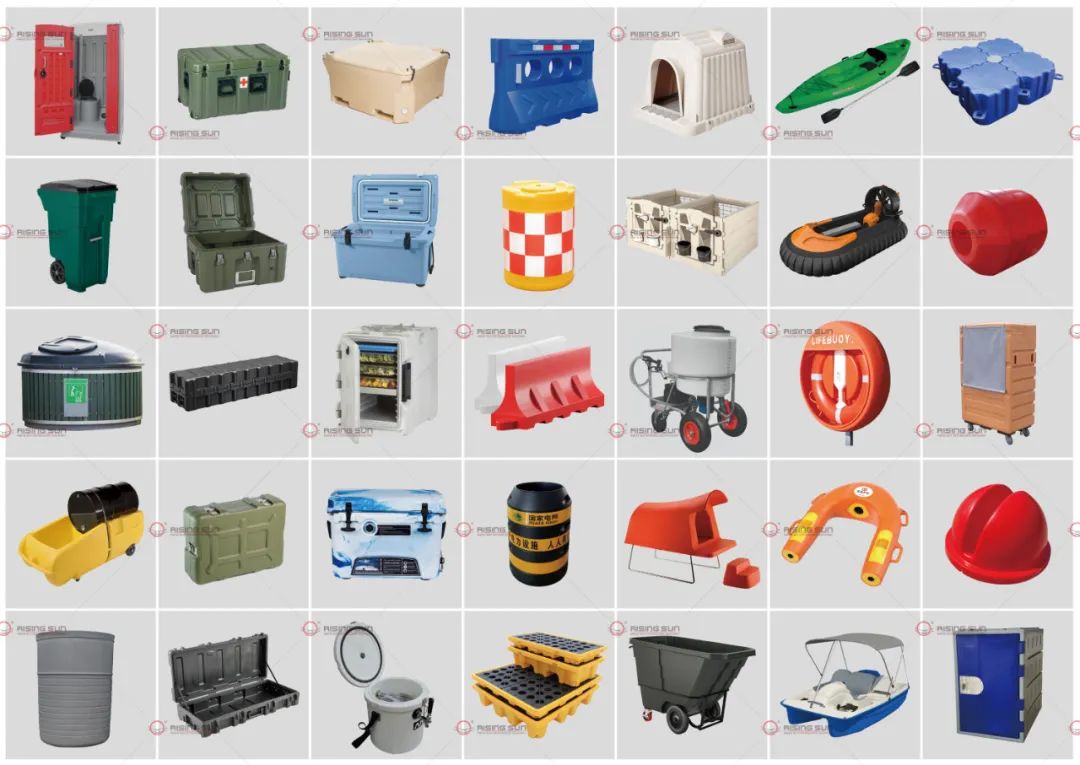

Listed below are some other rotomolding application areas, welcome to consult us to develop your area!