Rotomolding products are widely used in the automotive field because of their unique advantages!

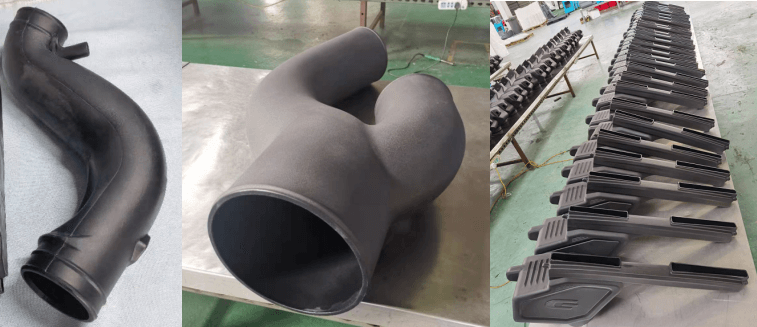

We are currently dealing with a lot of them, and the production demand is very large, such as fenders, car shells, driving platforms, urea tanks, hydraulic oil tanks, diesel tanks, gasoline tanks, bumpers, air intake pipes, air ducts... etc. can all be customized and mass-produced through rotomolding!

Its basic advantages are very obvious!

Advantages:

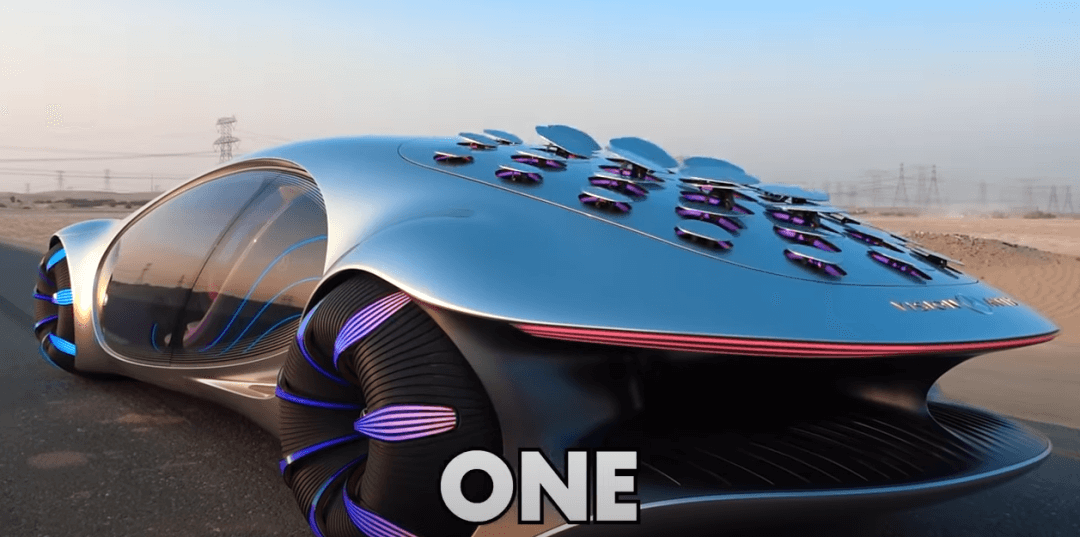

1. Strong design, can meet some special requirements of assembly, such as concept cars, high-end customized models;

2. Low mold customization cost and short cycle;

3. Good toughness and strong impact resistance of the product;

4. Gorgeous colors can be customized;

5. Recyclable and reusable;

6. The brand logo is directly molded on the product, which is a more high-end configuration;

7. One-piece molding reduces the risk of leakage;

8. According to assembly requirements, it can be made into inserts and directly molded and wrapped;

9. Corrosion resistance;

10. Longer service life;

11. Other advantages...

Customization and production of auto parts and pipes:

Customization and production of fuel tanks, urea tanks and other containers:

Customization and production of fenders:

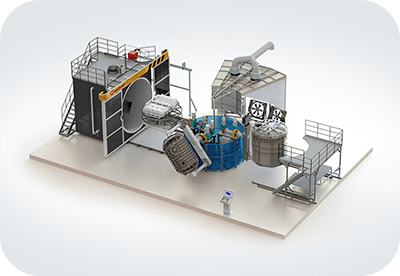

Rising Sun has currently developed a variety of machines, with mature rotomoding machines and rotational moulds sold to more than 70 countries around the world, most of which are oven-type rotomolding machine that can achieve mass production of rotomoulded pallets!

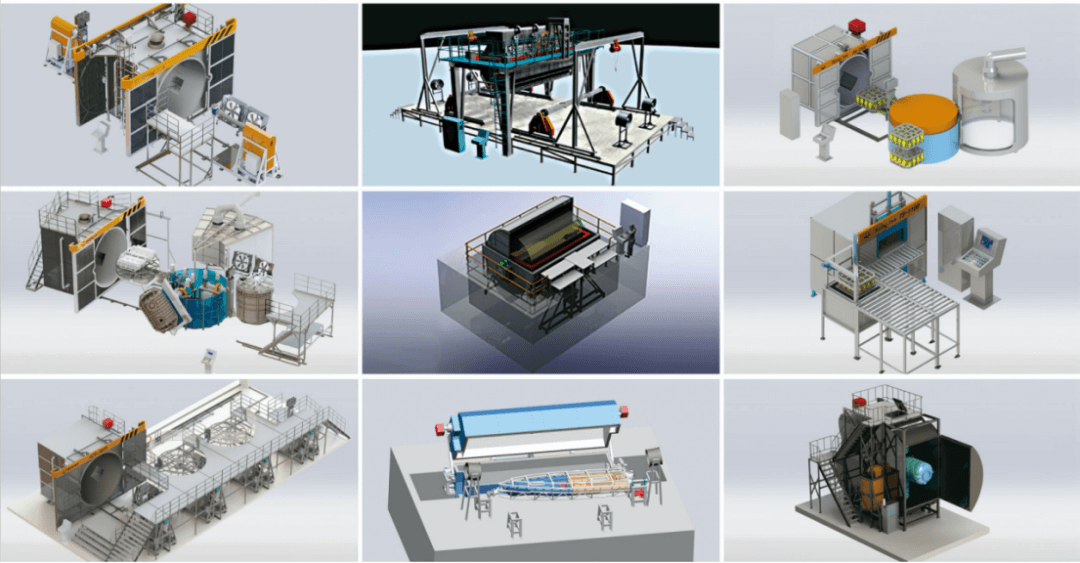

Rotomolding Machines: