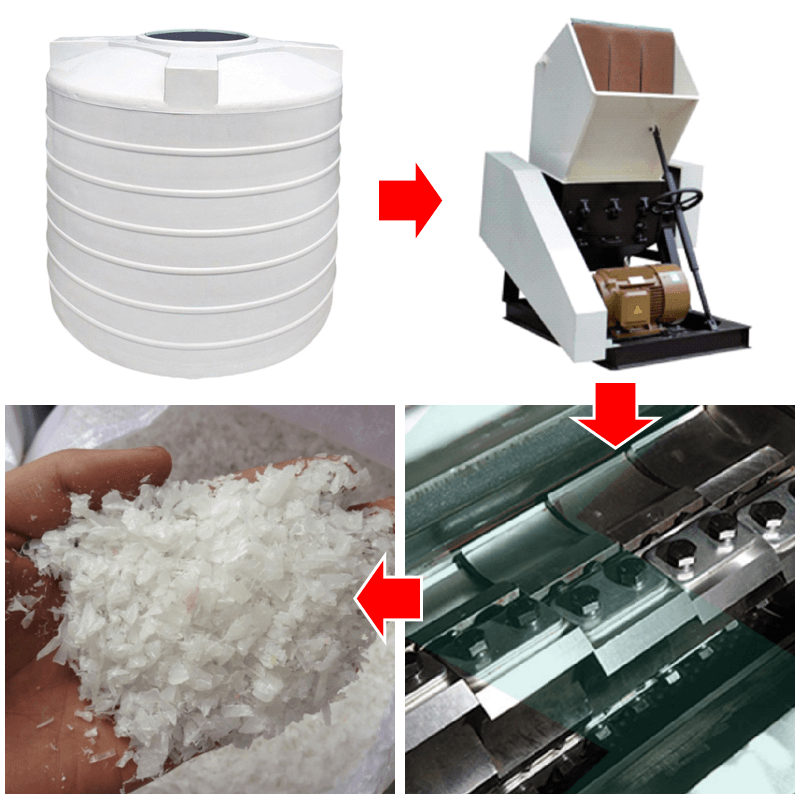

At present, the rotomolding materials we used are mainly polyethylene. One of the important advantages is that thermoplastics can be reused!

Many customers who focus on recycling will ask how to recycle rotomolding waste. Here we share the equipment we commonly use in plastic recycling: crusher.

How it works:

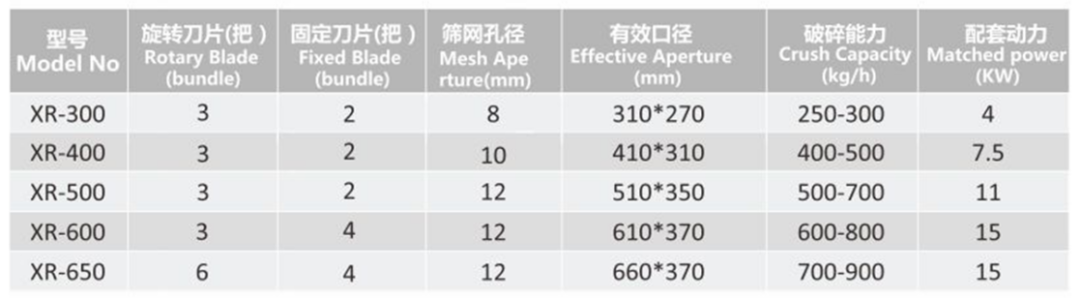

Several important factors in choosing a crusher:

1)blade

Polyethylene is the most commonly used material for rotomolding. Considering the difficulty of crushing the material, we usually choose blades with good wear resistance and high strength.

2)Screen

Screen the fine particles after cutting!

The smaller the diameter of the screening, the more convenient the subsequent processing will be, but it will also increase our cutting time. Therefore, it is very important to choose the corresponding appropriate aperture. We currently recommend using smaller apertures for smaller models.

3)Effective caliber

This usually determines the size of the recycled product we can put in.

For some oversized products, it is recommended to cut them before putting them into crushing, or choose a larger diameter crusher.

4)Crushing capacity

It refers to the weight that the crusher can crush per hour. It is a reference indicator. The shape and density of each feeding will have some impact on it.

5)Supporting power

Mainly refers to the power of the motor!

The greater the motor power, the higher the cutting bite force and crushing capacity of the motor transmission to the blade.

Regarding the rotomolding crusher, we have the following models recommended:

If you still have questions about choosing a crusher, welcome to communicate with us!