The application of the tray is firmly wide and it can be said that almost every enterprise will use it. But what we usually see in our daily life is the wooden tray shown in the following picture.

But if you want a fully designed tray with strong resistance and anti-deformation ability, the rotomolding manufacturers will often recommend you: rotomolding tray.

Key benefits

1.Compared with the wooden tray, the rotomolding tray is easier to recycle and reuse.

2.The rotomolding tray is better designed and can be customized according to the characteristics of the customers’ products.

3.Integrated molding can reduce manual operation and make the performance of the products more stable.

4.Compared with the broken wood structure,the tray made by blow molding and injection molding has a larger bearing limit and prevents it from rotting, which is easy to store.

5.No additional inspection such as fumigation.

6.The gorgeous colors of the goods can be changed casually to make them more eye-catching.

7.Logo can be molded directly to make the recipients feel more high-end operations of the suppliers.

8.Longer service life.

9. Other unexpected advantages!

Rotomolding tray

Good products pursue details! Even for a simple tray, our professional design team will often help customers to consider some problems, such as design a variety of products in line with the needs of the tray structure, the transport rules of the tray size and height, forklift position, dynamic bearing, tray weight, corner collision avoidance and so on.

At the same time, we will also participate in our customers’ production process and put forward some suggestions and auxiliary measures to help them achieve the production of high quality, high yield, high efficiency and low risk .

Besides the regular type, we also customize and produce large rotomolding trays for our customers and the size is two times of the regular tray. For example, the following one is mainly used by the customer to transport the large-scale agricultural and plant protection products and is only used by his own company. Steel pipe support is added at the bottom and the load- bearing capacity is up to 1.6 tons.

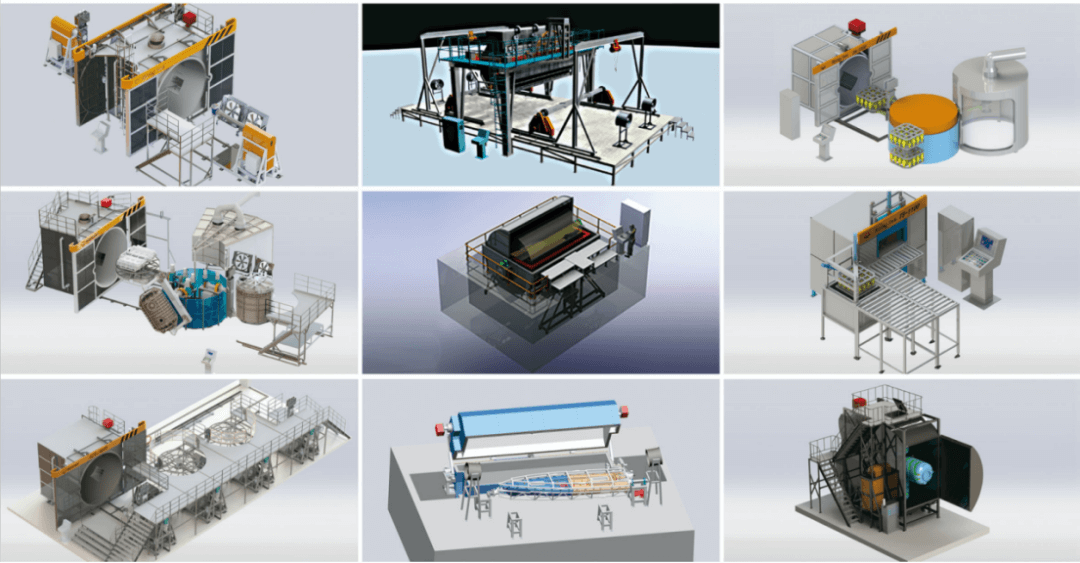

Rising Sun has developed a number of mature rotomolding equipment/ rotational mould. They have been sold to more than 70 countries around the world and most of the oven type rotomolding equipment can achieve mass production of rotomolding trays!

Rotomolding equipment exhibition

If you want to get more information, please contact us. We can provide a full set of detailed programs!