The selection of rotational moulds is an important part of the rotomolding process. The material, thickness, process, structure, etc. of the mold will directly affect the quality of the rotomoulded products!

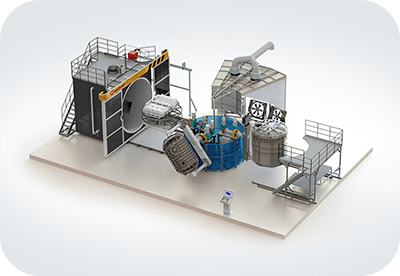

This time we share rotational steel moulds!

The main advantages of steel moulds:

1. The thickness of ordinary moulds is 1.5-3.5mm, with good thermal conductivity and fast heating;

2. Energy saving, environmental protection, and low emissions;

3. Light weight;

4. Easy to produce and very safe;

5. The mould material has high density and long service life;

6. Reasonable price.

In order to produce high-end seamless curved surfaces, reduce welding requirements, remove welding marks, and provide suitable moulds for products in different application fields, Rising Sun has developed a variety of rotational steel mould processes and constantly looking for new areas for improvement:

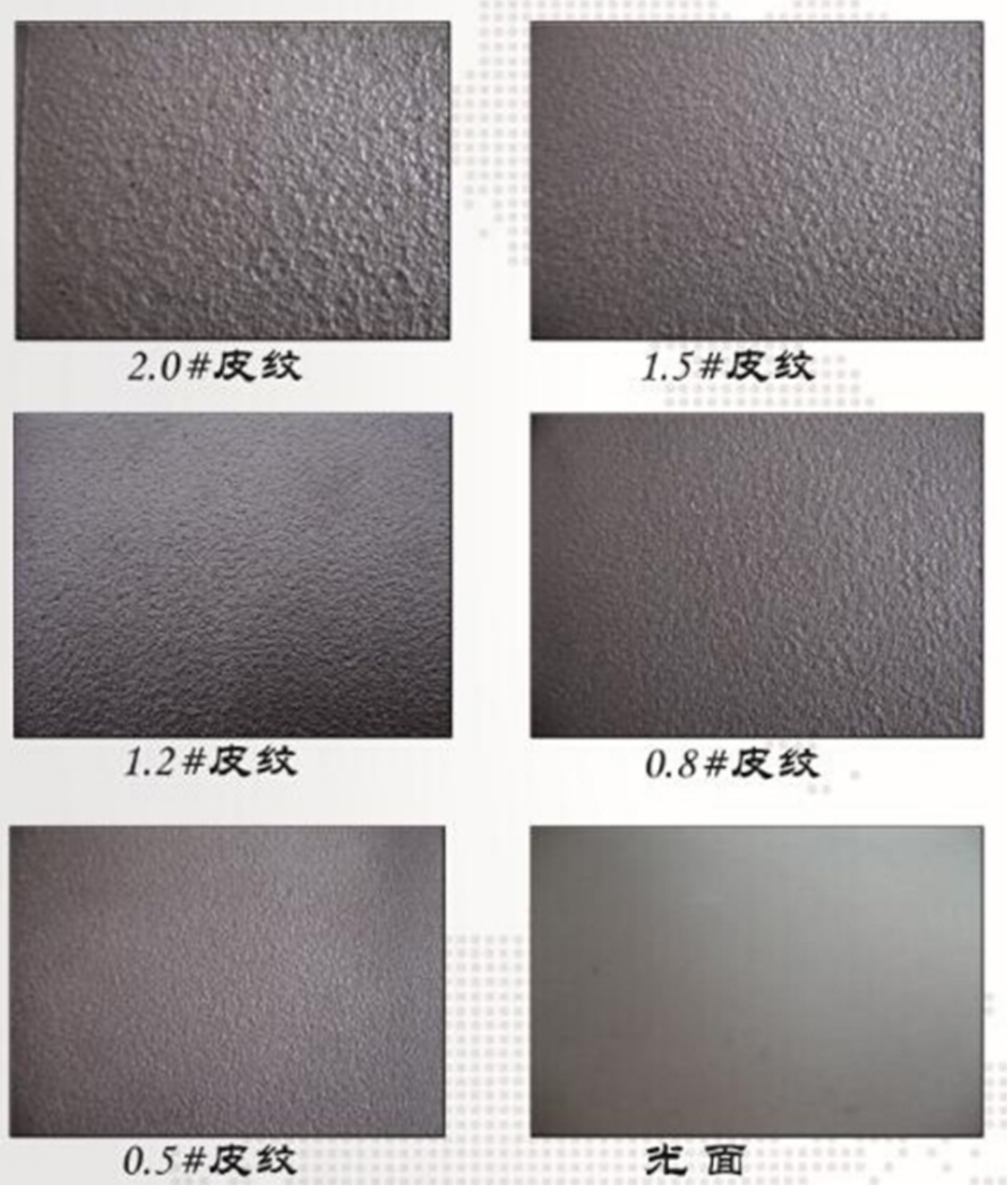

Various surface treatments:

At present, rotational steel moulds have been sold to more than 60 countries and regions including Europe, the United States, Australia, Southeast Asia, Africa, etc.!

The moulding process of steel moulds has been shared many times in top rotomolding associations and conferences domestic and abroad!

If you want to learn more about our steel mould technology, or if your existing products need mold development, please contact us!

Our sales manager will provide you with further explanation!