Do you have difficulty recruiting people?

Do you spend more time and energy because of the random stacking of raw material powder?

Do you suffer losses due to load-bearing and transportation problems?

This is not only a phenomenon in the rotomolding industry, but also a complaint in many industries.

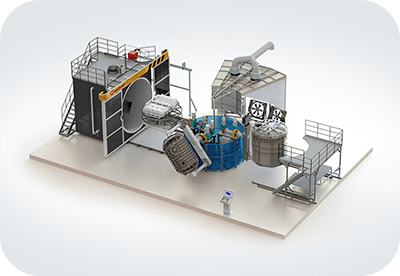

In order to solve these troubles of customers, Rising Sun launched a complete set of Load Ranger Weighing Control System!

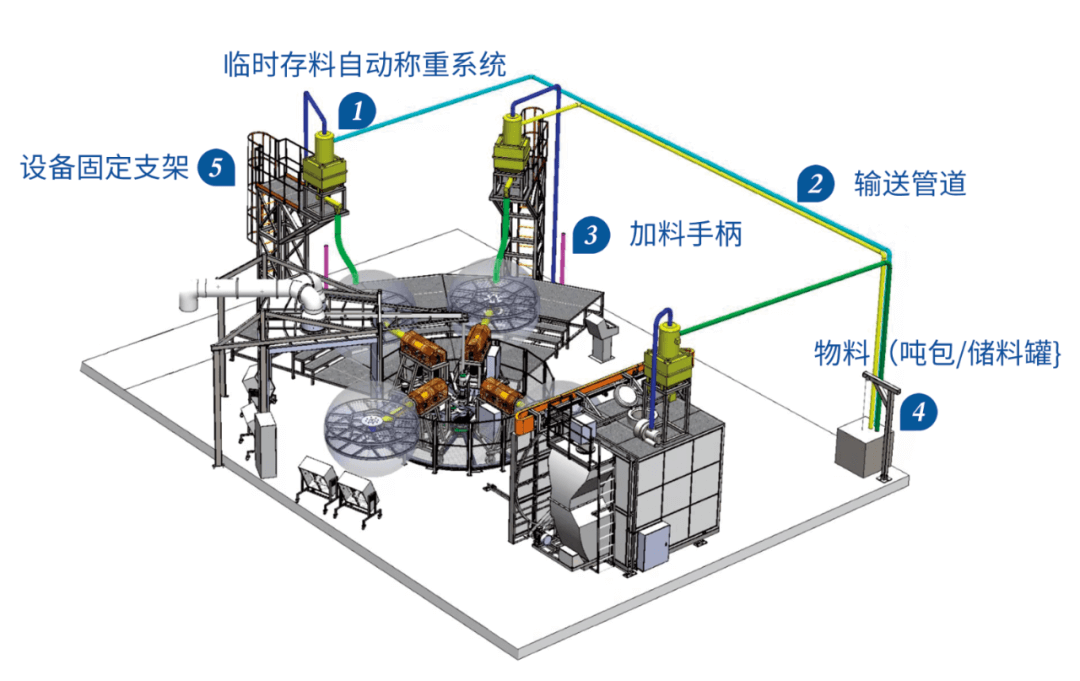

The main configuration :

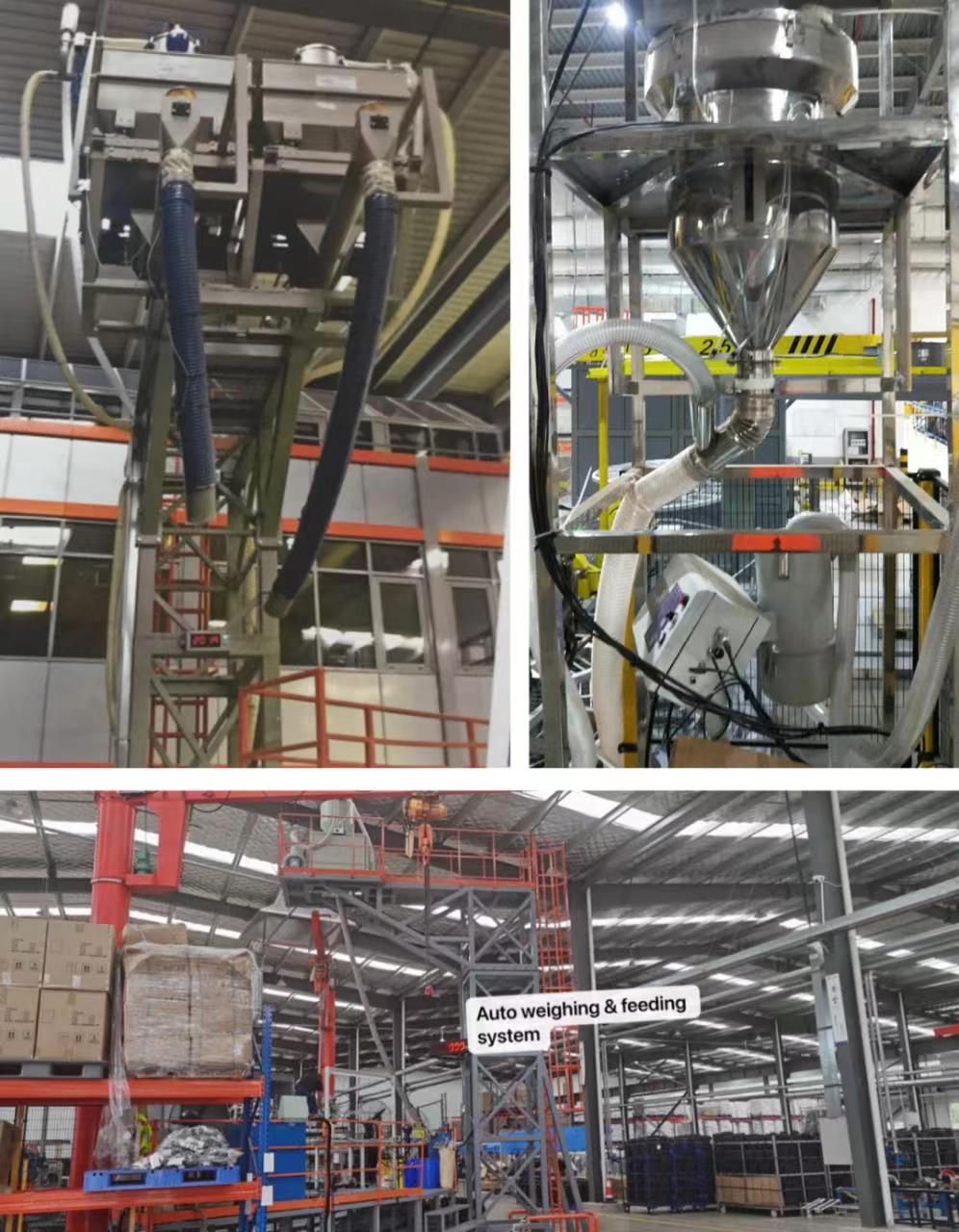

Automatic weighing system for temporary storage

Feeding gun

Conveying Pipe

Material center (ton bag/storage tank)

Fixing bracket

Function

Powder storage;

Powder transmission;

Powder preparation and weighing;

Package function enables multi-station and multi-mould feeding, etc.

Main Advantage:

The electric hoist device is used to lift the material onto the ton bag equipment, and the clamping device is used to fix the material discharge port on the collecting port of the ton bag machine. The ton bag machine is equipped with an anti-pollution device to effectively prevent the contamination of materials during lifting. When the material usage is reduced, a pneumatic flapping device is used to flap the material to fully concentrate the material at the collecting port and transport it to the feeding system.

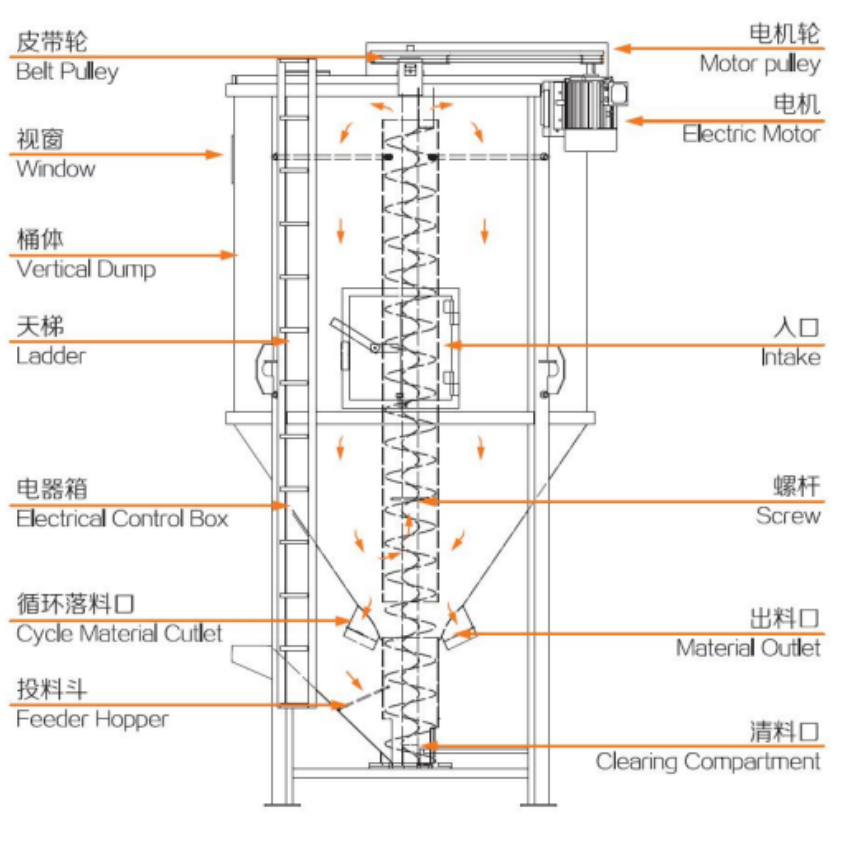

Can also be used in our stand mixer!

If a heating device is installed, the high-temperature gas can be blown into the raw material barrel through the fan, and the material can be dried in a short time while the raw material is tumbled up and down and stirred.

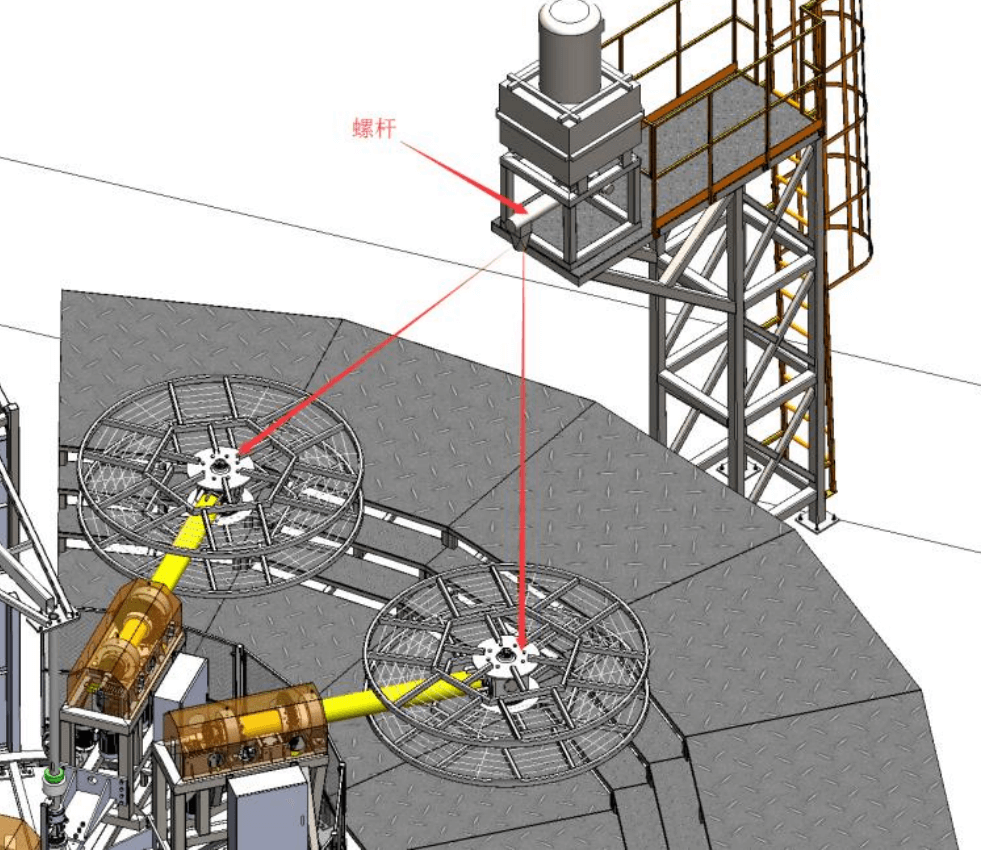

The machine utilizes the rapid rotation of the central screw to lift the raw materials from the bottom of the barrel from the center to the top, and then scatter them in an umbrella shape and return to the bottom. In this way, the raw materials roll up and down in the barrel and are stirred, and a large amount of raw materials can be evenly mixed in a short time. If a heating device is installed, the high-temperature gas can be blown into the raw material barrel by a fan, and the raw materials can be dried in a short time while they are rolled up and down and stirred.

It is worth noting that a single system can achieve the same color feeding of multiple stations and multiple molds!

Just imagine, would you be willing to spend more on recruiting, salary settlement, management personnel, security risks, etc., or would you be willing to spend this money on a set of equipment that provides fast, accurate and long-lasting services?

The main configuration :

Reduce material pollution

Accurate feeding measurement

Reduce labor and increase efficiency

Reduce dust pollution

High degree of automation

Images: