As we all know, steel corrosion is very common, resulting in huge economic losses; Pure plastic parts are not as strong as steel in impact resistance and puncture strength;Commonly used plastic pipe is also easy to damage in a variety of construction.

Steel lining plastic perfectly combines the strength of steel and the multi-characteristics of plastic material, which is mostly used for steel lining plastic storage tanks, pipelines and other transmission and storage parts, among which the life of high quality steel lining pipe can generally reach more than 50 years!

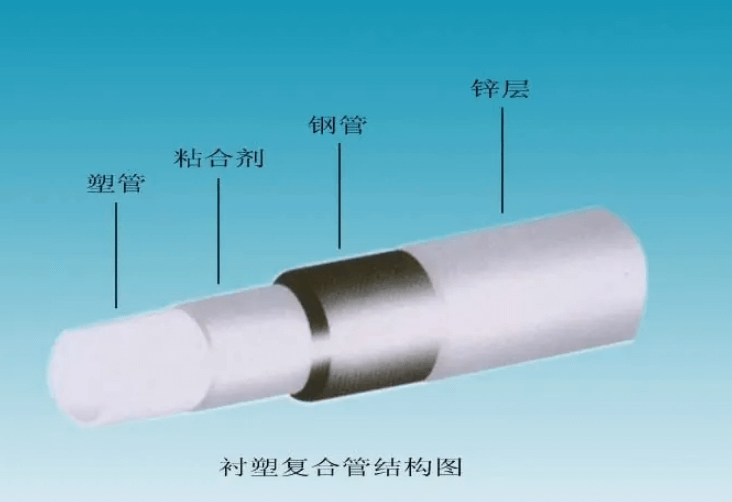

1)Structure:

The main materials: polyvinyl chloride (PVC), polyethylene (PE), polyolefin (PO), polypropylene (PP), polytetrafluoroethylene [PTFE,F4], etc.

01.Chemical industry

Process and discharge steel lining plastic pipes for transporting corrosive gases, liquids and solid powders in the industry of acid, alkali, salt manufacturing, fertilizer, pesticides, chemicals, rubber and plastics.

02.Power engineering

Return water transportation of process water, chemical water, waste residue and fly ash transportation.

03.Smelting industry

Transport of corrosive medium in metal smelting

04.Mining industry

Discharge of ore powder, pulp, slag and tailings;Backfill, ventilation, gas drainage and gunning

05.Pharmaceutical industry

Transport all kinds of corrosive media, sewage, waste water

06.Oil field & Gas field

Transport of oily sewage, gas field sewage, oil and gas mixture

07.Agricultural irrigation

Deep well pipe, filter pipe, culvert pipe, drain pipe, irrigation water supply pipe

08.Municipal industry

Steel lining plastic pipes for urban construction water, drinking water, fire water, heat return water, gas, natural gas , highway buried drainage and green belt irrigation.

2)Customer Product Display:

3)Machines:

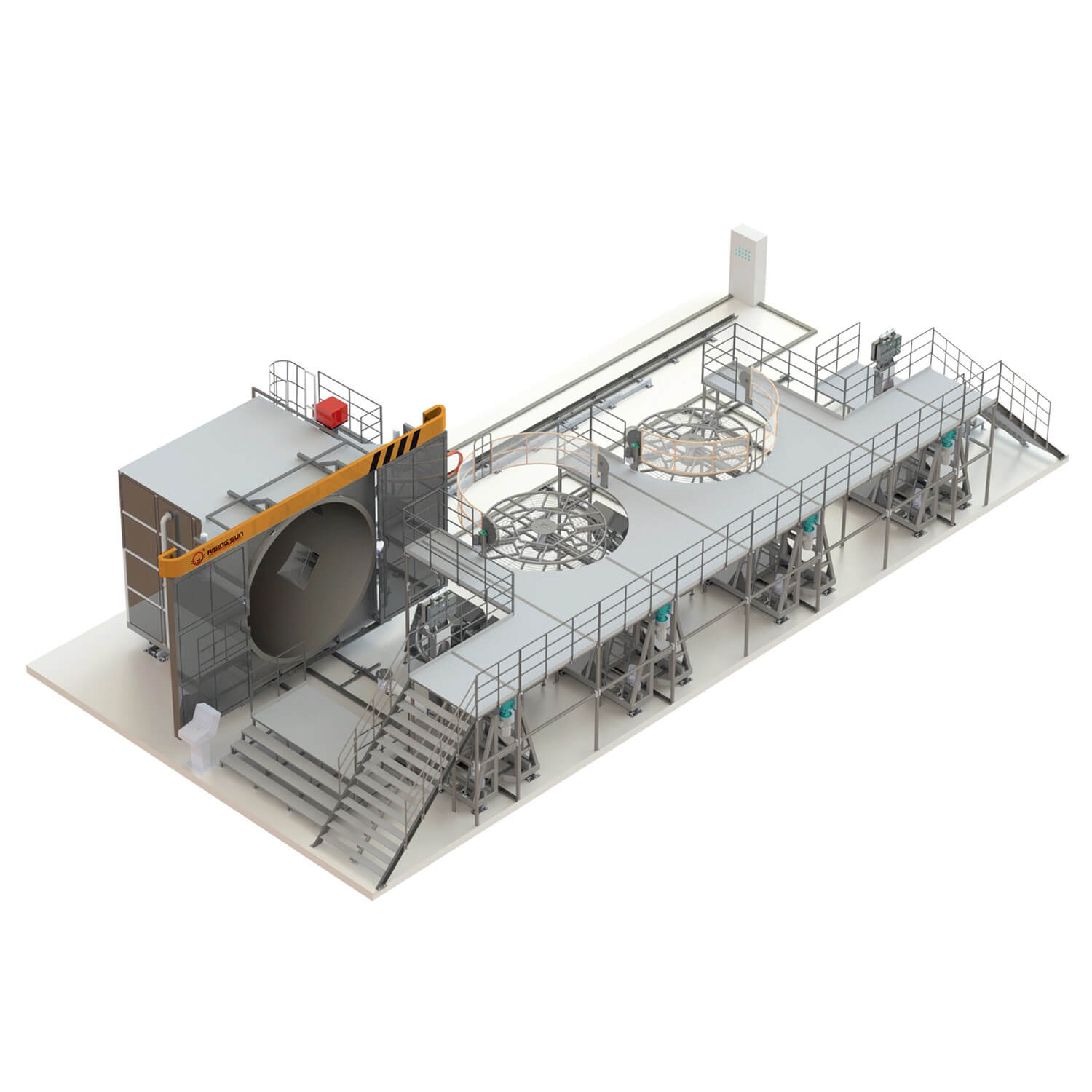

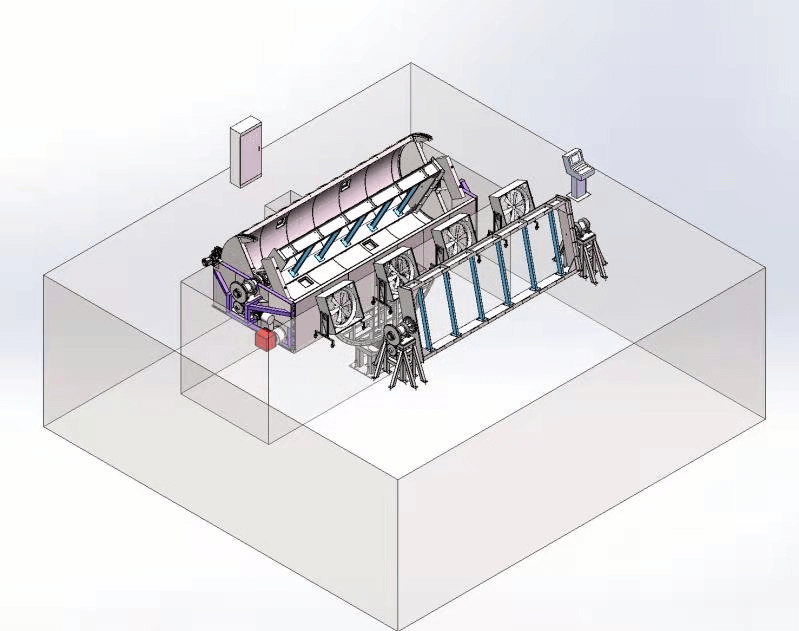

01 Shuttle rotomolding machine

With the front and back two rotating arms, this machine can produce a variety of large and medium-sized special-shaped pipe!

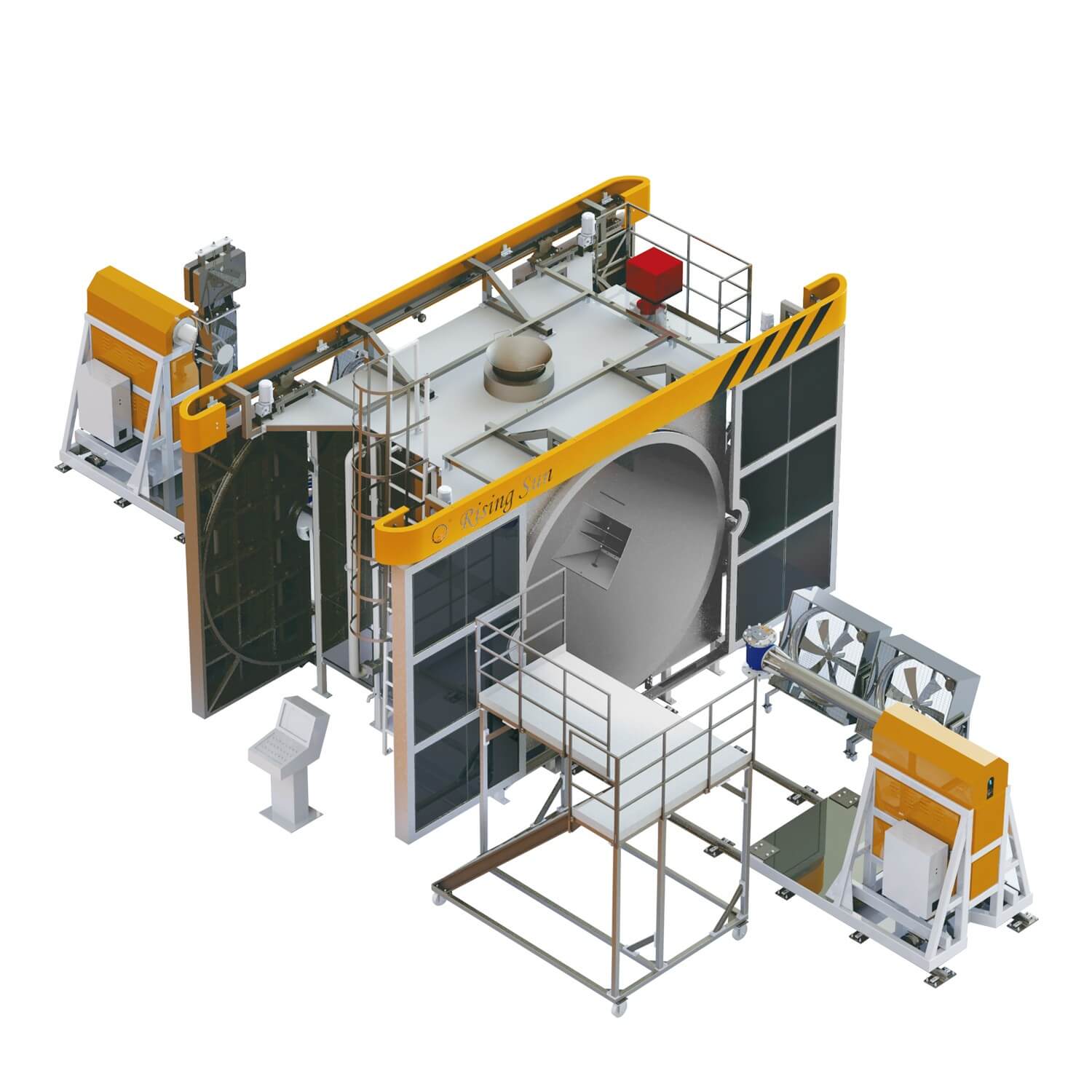

02 Carrousel rotomolding machine

The machine can be carried out multi-station rotation production, suitable for mass production. It provides nearly 30 percent more efficiency than the shuttle rotomolding machine.

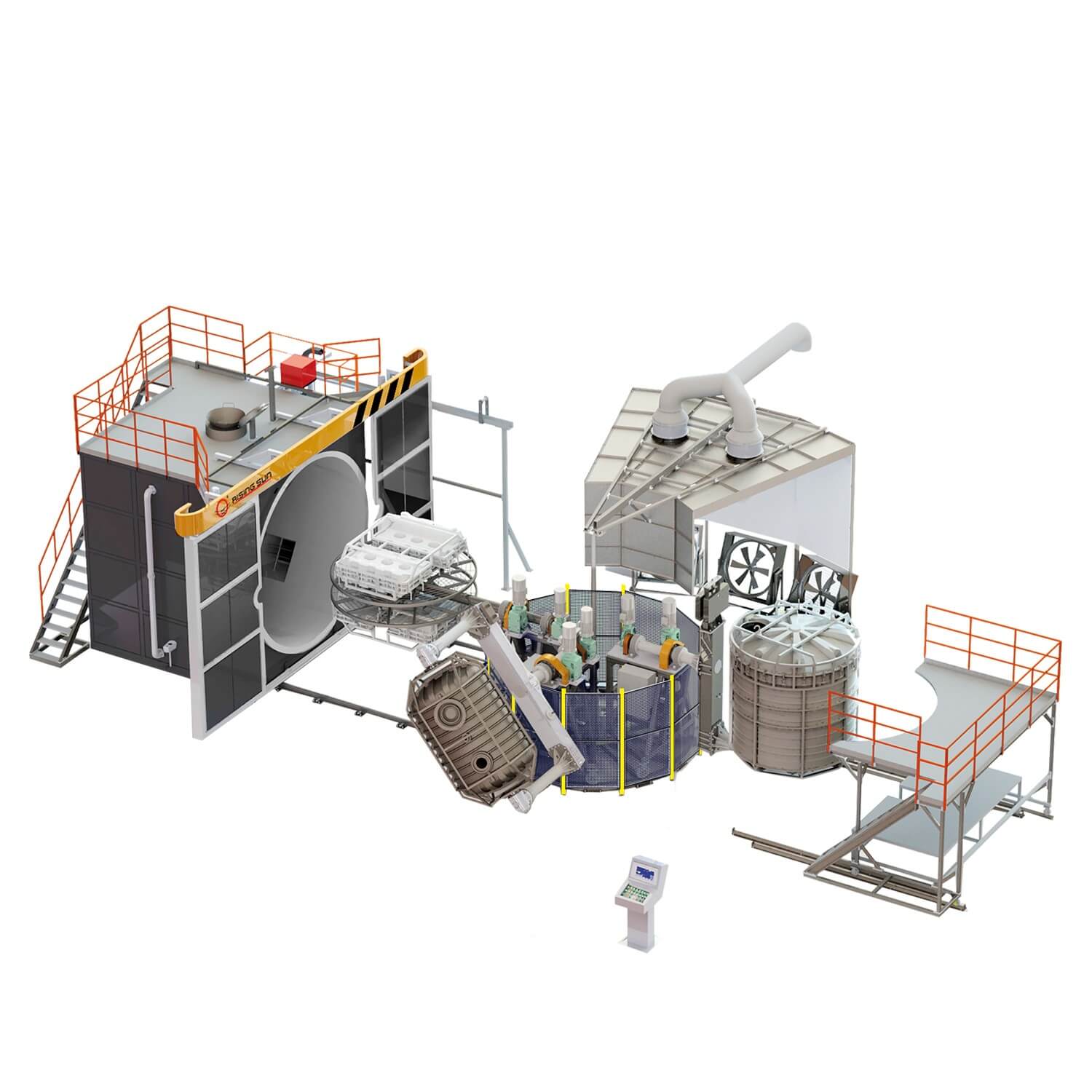

03 Multi-arm rotomolding machine

This machine is more flexible to use and operate, and more efficient to produce. If you have enough room in your factory, consider this one.

04 Oven swing machine

The machine is simple to operate, economical and efficient.

Our company's current standard machine is suitable for producing the vast majority of steel lining plastic products! In order to provide accurate service, our professional sales representatives will fully communicate with you, according to the lining material, product weight, production demand, plant configuration, etc., to help you choose the right model and configuration!

4) Customer Production Line: