Steel-lined plastic pipe is a kind of thermoplastic pipe with excellent chemical stability, which is formed by cold drawing or rotational molding. It not only has the mechanical properties of steel pipe, but also has the characteristics of plastic pipe, such as corrosion resistance, slow accumulation of stains, not easy to grow microorganisms. It is an ideal pipeline for transporting acid, alkali, salt, corrosive gas and other media.

At present, rotational molding has a very wide range of applications in the steel-lined plastic pipe of seawater pipeline, chemical storage tank, chemical pipeline and so on. The lining can be made of PE,ETFE,F40,PO, etc.

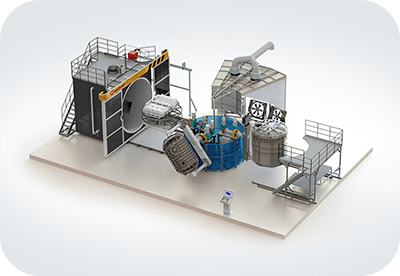

At present, our company has more than 10 sets of equipment adopting plastic-lined steel, including various types of turret and shuttle machines, as well as rock n toll machines with oven for large pipeline.

The model Shuttle 2500, we installed in Taiwan last year, is dedicated to the production of lining made of ETFE. Because the material has a high melting point, we use a Maxon burner, which can reach a maximum burning temperature of 450 degrees.

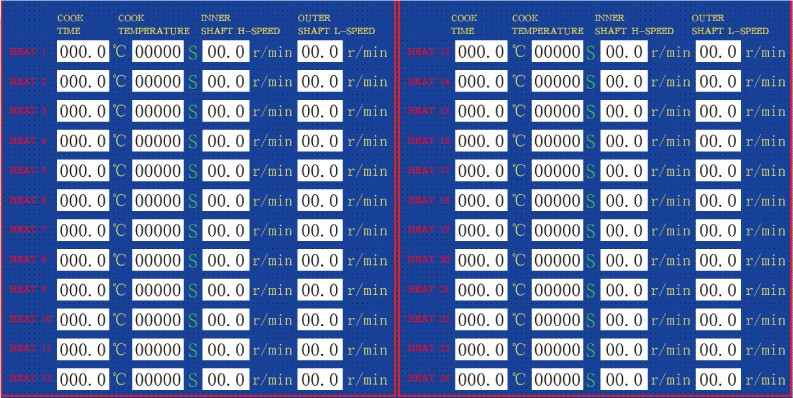

According to the customer's production requirements, 24 levels of heating temperature, time and mainshaft and countershaft speed can be set during the same heating process. Compared with the ordinary equipment, we have customized the design of heating tunnel and material selection, the bearing capacity of the arm according to the material and product characteristics. The equipment has an excellent performance in high temperature. After 12 hours of uninterrupted 450 degrees high temperature test, the arm and heating tunnel have been working normally. The equipment has been put into operation for nearly 2 years, and its operation has been very stable, and customers have a high evaluation on it.