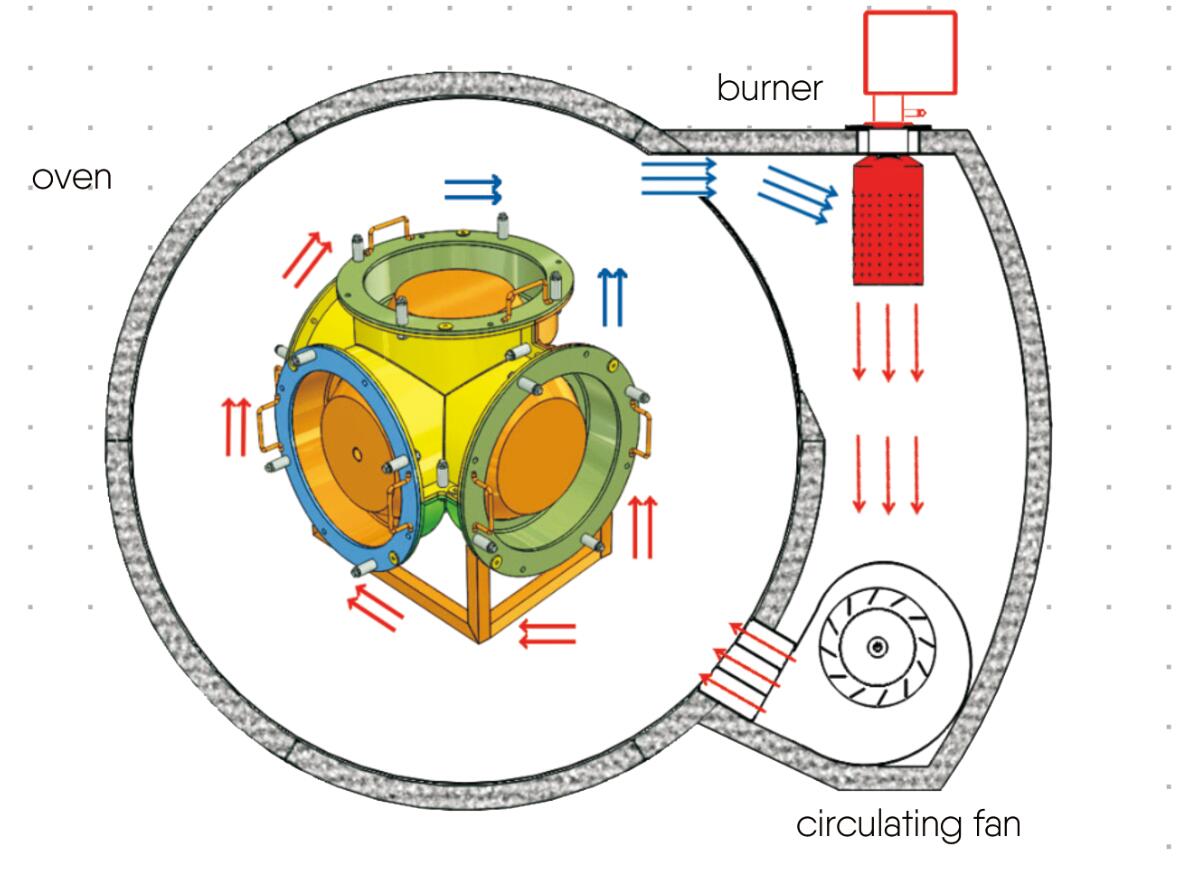

1、Hot air recycling;

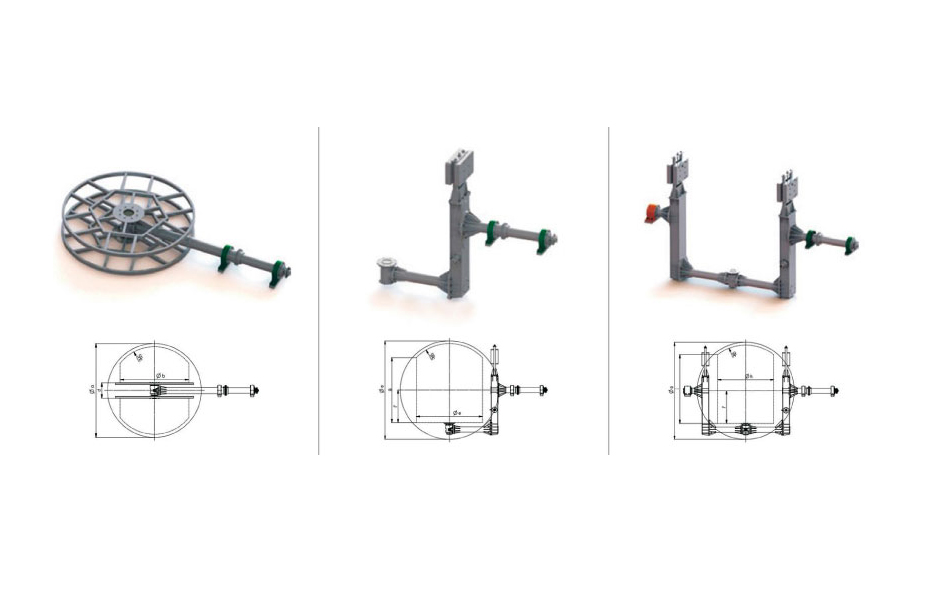

2、High oven volume utilization;

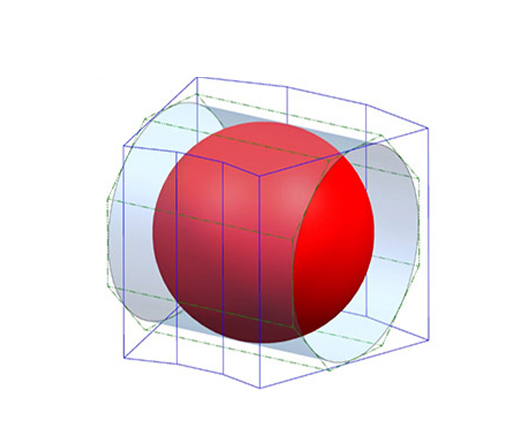

3、The mold is heated evenly;

4、The equivalent heat absorption area of the oven is small, thus reducing energy consumption;

5、The oven is tightly sealed to reduce the heat loss inside the oven;

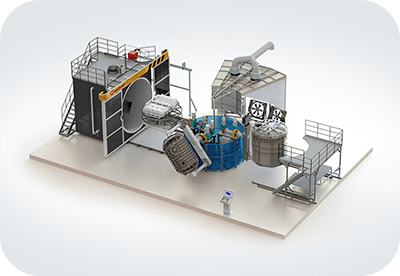

6、Compared with the traditional heating method, the moulding time of the product can be shortened by 50%, realizing energy saving and increasing efficiency;

7、The energy burns completely, and the PM2.5 emission value is low;

8、Energy saving, fewer emissions, higher、environmental protection, higher production efficiency