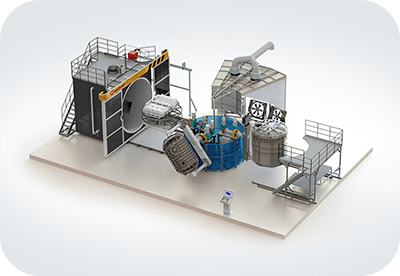

Rotomolding solutions - arm selection and customization

The rotating arm is an important part of the rotomolding machine, which enables the mould to be rotated or positioned in multiple directions in the oven. Choosing a suitable rotating arm is an important part of our customers' selection of rotomolding machine!

Many professional customers will carefully understand the type, load-bearing capacity, rotation range, rotation method, control method, etc. of the rotational arm, so as to make early plans for subsequent production. Of course, for many new customers entering the industry, we will also recommend suitable rotational arms according to the products, output, demoulding requirements, etc. that the customers need to produce, and even do computer simulation display and condition analysis.

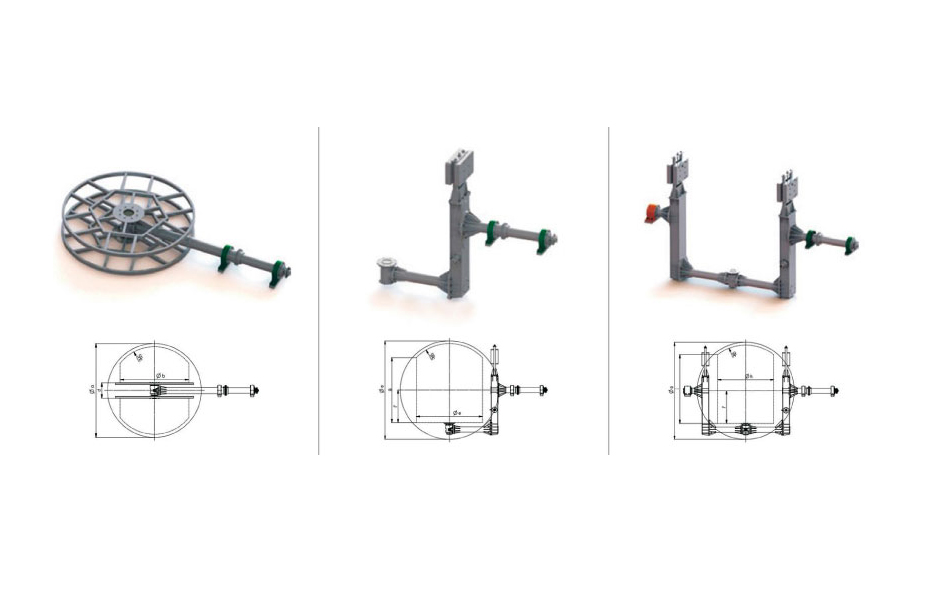

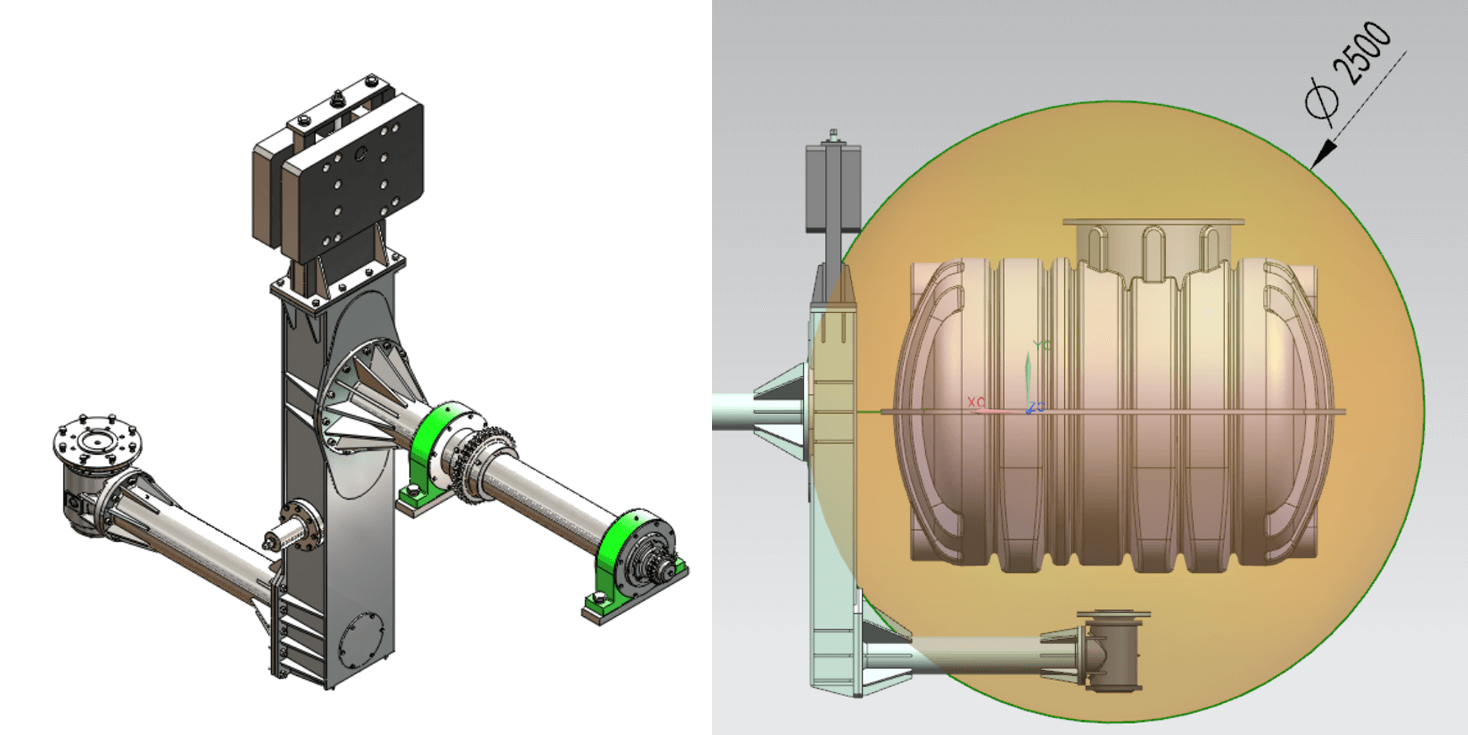

(1)Straight Arm

It is mostly used in shuttle or carousel rotomolding machine.

The rotor can fix with spiders,enables multiple moulds to be placed and fired simultaneously!

For larger products and seldom-changed moulds, the moulds can be directly fixed to the rotor via flange connection.

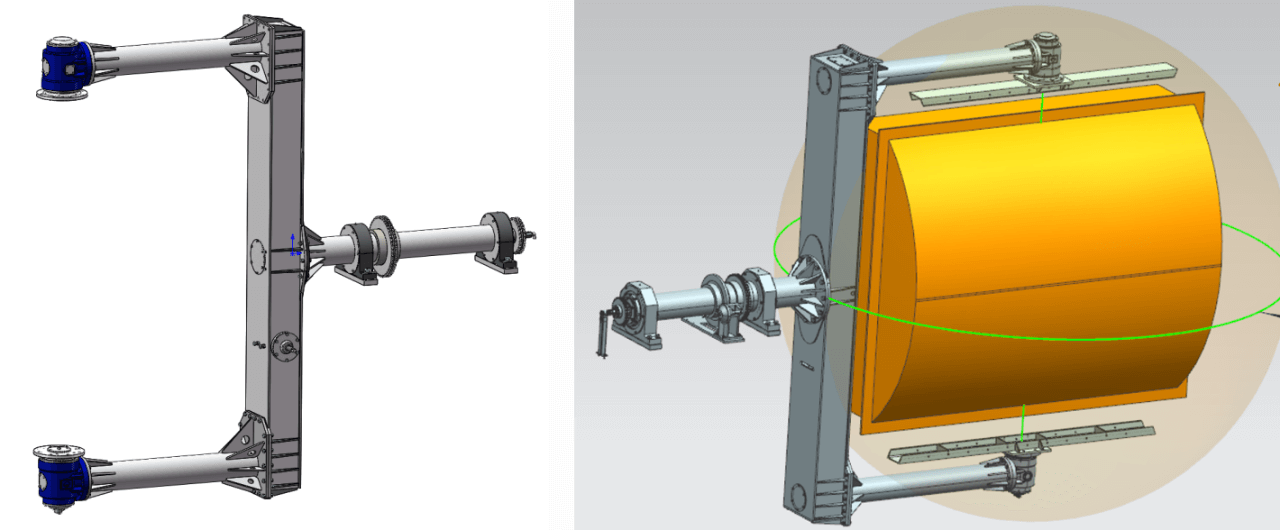

(2)L Shaped Arm

When the oven size is limited, the L-shaped arm effectively improves the space utilization of the oven, making it easier to produce larger products and some special products.

(3)C Shaped Arm

While improving the utilization of the oven space, it can also provide stable mould support for large products. It is also very suitable for demoulding some special products, such as S-shaped slides.

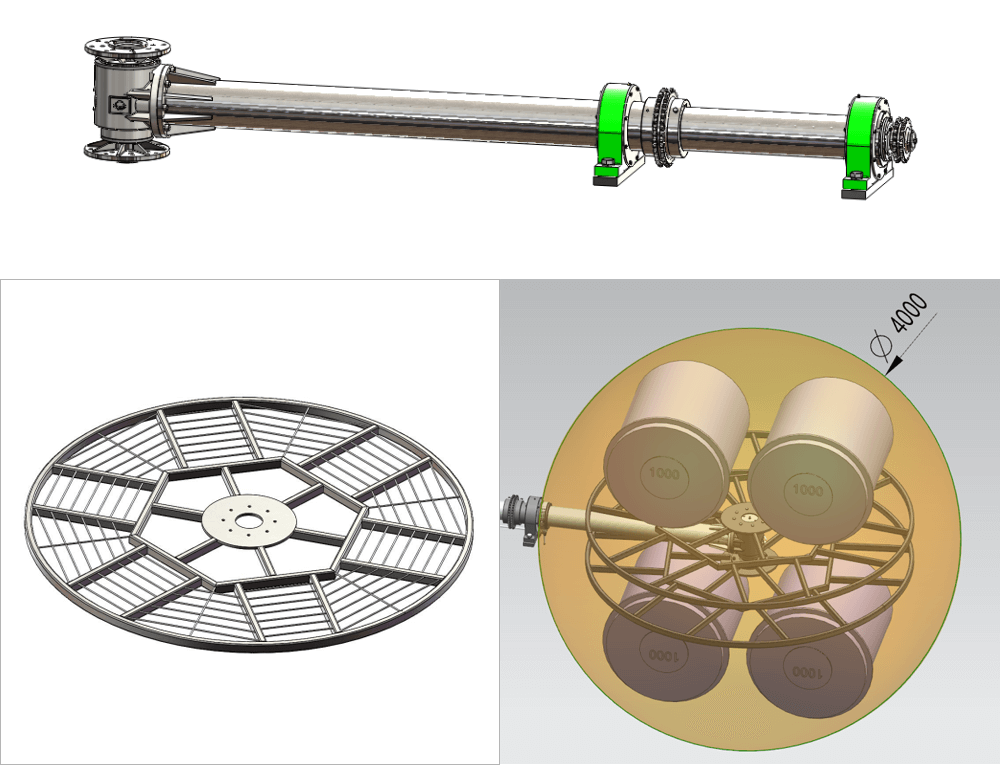

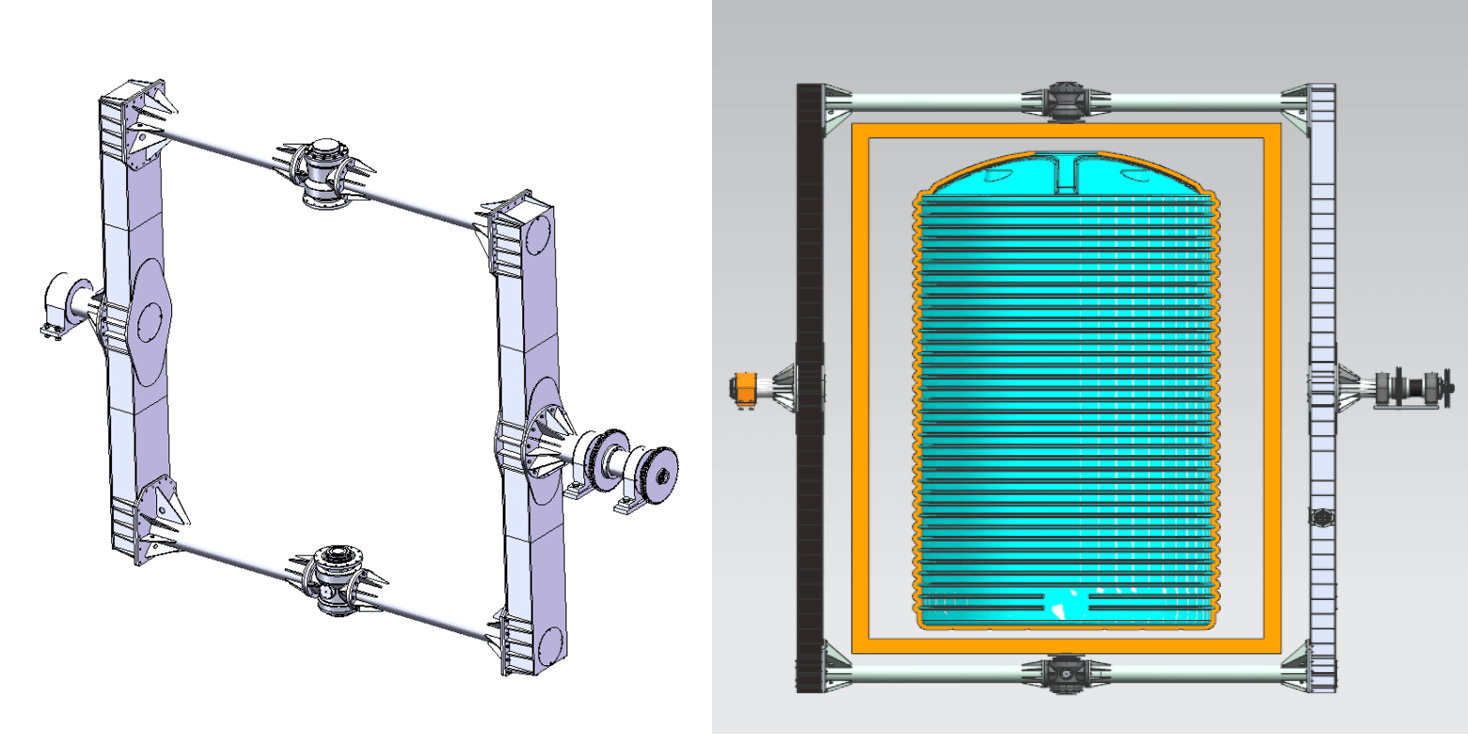

(4)Double support straight arm

It is usually used in larger shuttle oven machine to produce larger and heavier rotational products. Double-point support can provide large load-bearing capacity.

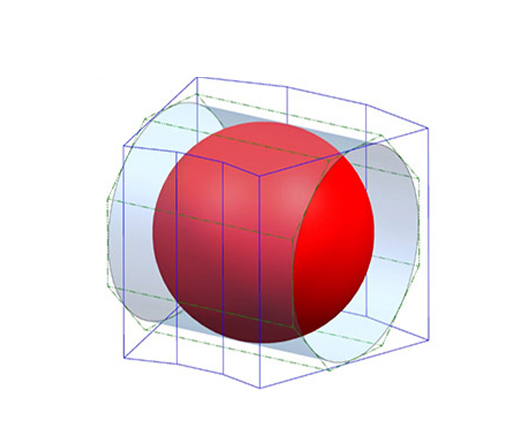

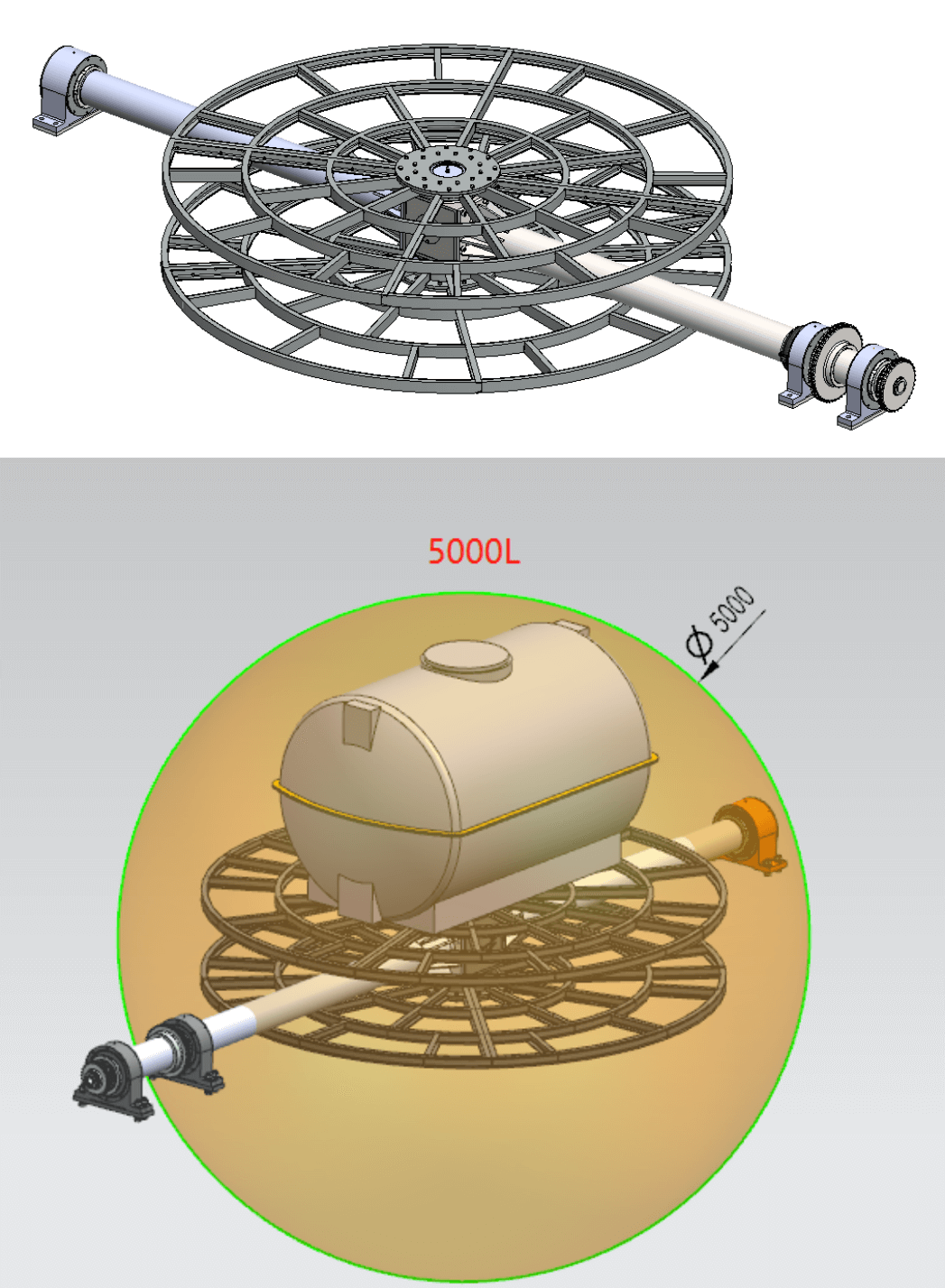

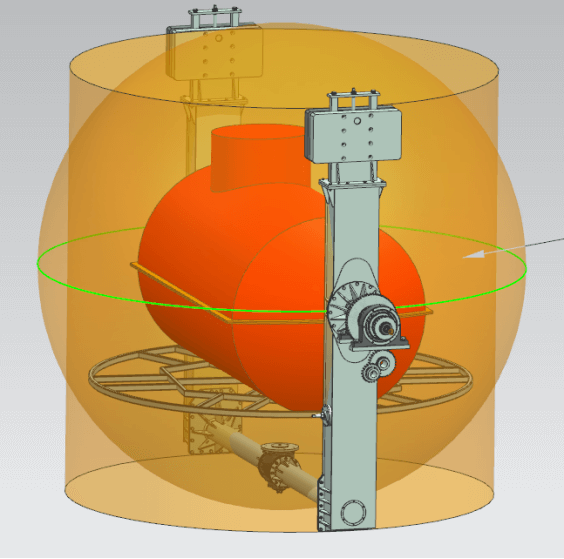

(5)O Shaped Arm

Make the most of the space in the large rotomolding oven and provide a larger and more stable rotating load-bearing environment for the rotational mould

With the inner frame, the rotation can be more stable.

(6)U Shaped Arm,Rock N Roll machine arms and other arms can be customized according to customer requirements!

Before the design and use of the rotational arm, we have strict quality control measures, including early CAE analysis, demonstration/heat treatment/application of mid-stage materials, and improvement based on end-customer feedback. With market feedback and improvements, our rotational arm application has become very mature and has been used in the production of products in various fields, and will continue to be optimized in detail!

Do you have the same problem in choosing rotational arms? Feel free to contact us!